Interested in Cleaning?

Get Cleaning articles, news and videos right in your inbox! Sign up now.

Cleaning + Get AlertsThe Big Bear Area Regional Wastewater Agency in Big Bear City, Calif., had capacity issues where its sanitary sewers turned 90 degrees. The staff monitored flows at seven problem areas using meters from a company that later went out of business.

At that point plant superintendent Joe Hanford lost the ability to access real-time data through a Web server. Without a warning system, high-flow events led to occasional sanitary sewer overflows (SSOs).

The agency lived with the situation for two years as it investigated companies and solutions. “There didn’t seem to be a lot of options at the time,” says Hanford. “Then a Hach Company representative demonstrated the Marsh-McBirney Flo-Dar flowmeters with a Data Delivery Services (DDS) program. They seemed suitable for our application, so I signed a three-year contract.”

The program uses Web-enabled radar velocity sensors with surcharge velocity sensors and cellular wireless flow loggers that transmit data to a secure website. Hach personnel installed and maintain the meters. Since enrolling in the program in November 2010, the agency saves $600 per month in labor and materials and receives reliable, accurate, real-time data, according to Hanford.

Comprehensive package

The 4.9 mgd Big Bear Area Regional Wastewater Treatment plant handles flows of 2.4 mgd from Big Bear Valley and three other member agencies. Each agency operates its own collection system but delivers wastewater via the regional agency’s interceptors. The agency maintains 15.5 miles of 6- to 21-inch sanitary sewers and interceptors.

Every week, Hanford’s crew checked the batteries in the original flowmeters and deragged fouled sensors as part of field work. The sensors, submerged in the stream, would send erratic velocity and depth measurements when material adhered to them. “We never trusted the data completely because the flows jumped around a lot,” says Hanford. “We also had too many instances where the cellular wireless connection went down at a time when it was crucial to have real-time information.”

The DDS program enabled Hanford to obtain flow data from three critical sites using Flo-Dar meters with optional surcharge velocity sensors. The units are owned and maintained by Hach-certified personnel. The program also allowed Hanford to trade in three original sensors.

“Receiving credit toward the new units was one reason we selected Hach,” says Hanford. “They also check the batteries, calibrate the meters, and make certain that they read properly.” Hach technicians installed the units in less than two days. Hanford sent one of his team members to observe so that he understood how everything worked.

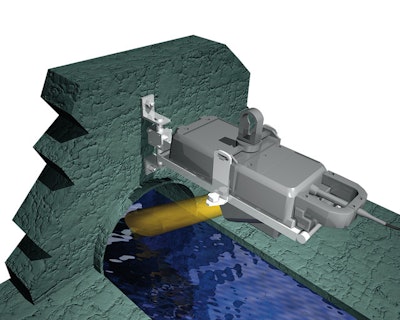

A four-bolt bracket mounted on manhole walls suspends the units above the stream. The 60-inch operating range from housing to the bottom of the pipe has an accuracy of plus-or-minus 1 percent.

The flowmeter combines digital Doppler radar velocity sensing technology with ultrasonic pulse echo depth sensing to measure flows. Mounting units above the water eliminates sensor fouling and accuracy problems, including sensor disturbances, high solids content, and distribution of reflectors.

Meters operate accurately at 14 to 122 degrees F, in shallow and caustic flows, in large man-made channels, and at velocities up to 20 feet per second. When the surcharge velocity sensor becomes submerged, it sends an alarm while monitoring flows.

Peace of mind

The units download flow data via a FL900 series cellular wireless flow logger to a secure website. The technology is so reliable that the company guarantees the data or users receive a month of service free for a site.

“We had a major rainstorm with heavy inflow and infiltration just before Christmas,” says Hanford. “It was a luxury to sit at the plant and receive real-time data through Hach’s Web server on the depth in problem manholes. Seeing a smooth flow transition assured us that the system was all right and we weren’t about to have a SSO.”

The program enabled the agency to improve its long-term planning for expansions or upgrades. “We did a capacity analysis on our sewer system to determine what flows we will experience on peak days,” says Hanford. “Such tools help us decide if improvements are necessary and when to implement them.”

The tools also help him identify the sources of surcharges. The agency has three meters hard-piped into lines to measure member agency flows for invoicing. “If we have a SSO, I can look at the data and pinpoint which member’s flow increased at which section of pipeline to surcharge our pipe,” says Hanford. “That’s good data for the other agencies to have, so I gave them my username and password to the website.”

The dashboard mapping feature of FSDATA, the Web-based management software, uses maps with color-coded marker displays to indicate meter status. The quick graph feature displays the last seven days of level and velocity (fps and gpm) data.

“By selecting days and parameters, I can generate reports in spreadsheet or graph format, then export them as portable document files,” says Hanford. “When it’s raining, I especially enjoy logging on from my home computer and getting accurate, real-time information about sewer conditions.”