Interested in Stormwater?

Get Stormwater articles, news and videos right in your inbox! Sign up now.

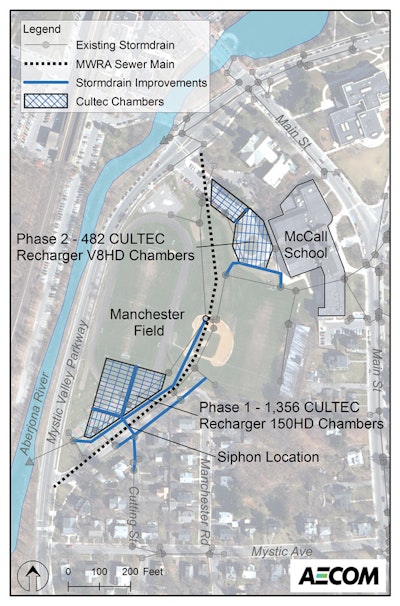

Stormwater + Get AlertsEven a two-year storm surcharged the stormwater system in Winchester, Mass., flooding the main athletic field and its neighborhood. The system drains about 67 acres of the Aberjona River watershed.

Portions of the town, originally named Waterfield, lie in a 100-year floodplain, and seasonal high groundwater in the project area averages 9.2 feet. The river ran through what became the athletic field until it was relocated in the 1950s.

In 2007, the town contracted the AECOM Environment engineering firm to study the drainage problem before replacing some of the field with synthetic turf. Engineers found that four separate stormwater systems collected runoff that discharged into the river through a 27-inch outfall. The system was so undersized that it backed up even when there was no resistance from river flooding.

Jacob San Antonio, P.E., AECOM water resource engineer, recommended upgrading the system for storms up to and including a 25-year, 24-hour storm. Since the 4-acre site had no room for aboveground retention or detention ponds, he selected underground stormwater chambers from CULTEC Inc. to prevent surcharges and increase storage when the river rose.

The first phase of the project ended in March. “We’re happy to provide some relief to this neighborhood,” says Beth Rudolph, P.E., town engineer. “We won’t know how well the system works until it is completed and we have a significant storm, but so far we haven’t had any flooding.”

Convoluted conveyance

Winchester, eight miles north of Boston, has a multi-year flood mitigation program with projects in the Aberjona River to reduce flooding. “Our stormwater upgrade tied right in because it reduces runoff to the river,” says Rudolph.

The greatest challenge was untangling the Manchester Road drainage system. Two separate 12-inch reinforced concrete pipes conveying water to the main trunk line under Manchester Field formed a loop that backed up runoff and flooded the road. One line flowed through a siphon that crossed below a 48-inch sewer main owned by the Massachusetts Water Resources Authority (MWRA).

“Green Acres Landscape & Construction Co. abandoned the looped drainage system, increased the size of the drainage pipes in Manchester Road, and increased the slope for better drainage,” says Rudolph. “They upsized the pipe crossing the sewer to 30 inches and installed a check valve at the tie-in so runoff can drain as river levels rise.”

Meanwhile, other crews from the Lakeville-based company installed 1,356 Recharger 150HD detention chambers in three zones fed by two 24-inch HDPE headers. The system occupies 36,000 square feet of the athletic field and provides nearly 500,000 cubic feet of storage. The low-profile chambers are 33 inches wide and 18.5 inches tall and offer 4.89 cubic feet of storage per foot.

After workers excavated, dewatered, and prepared the subgrade, they laid down nonwoven filter fabric, spread and compacted six inches of 1- to 2-inch washed stone, and assembled the chambers.

“They have a fully formed end wall and an open large rib with a closed smaller rib for an easy interlocking connection,” says Anthony Amaral Jr., assistant project manager. “We built the beds in stages, laying only as many laterals as we could backfill with stone.” To keep the chambers from moving, workers slowly distributed stone over the crowns, allowing it to build up between the rows and cover them by six inches.

They covered the installation with another sheet of fabric, overlapping the edges by 24 inches, before backfilling with soil in 6-inch lifts, then compacting the soil.

River runs through it

Connecting the Manchester Road drainage system to the detention chambers required replacing and relocating the siphon, adding two manholes, upgrading the 12-inch line to 30-inch RCP, dewatering, and pipe jacking.

“We dealt with an enormous amount of groundwater because we were working where the river used to run,” says Amaral. “The siphon alone was in 10 feet of groundwater. Excavations required numerous large pumps with filtration tanks running around the clock.”

Dewatering also included sumps at the bottoms of the pits, wellpoint dewatering around the pipe-jacking area, and a 12-inch-wide, 30-foot-deep well between pits. Workers pipe-jacked 45 feet of 30-inch pipe under the sewer to connect the two manholes. The 24-inch HDPE pipe connecting the first manhole to the siphon had a flanged inline check valve to prevent backflow.

The second phase of the project began in July. Workers installed 556 Recharger V8 chambers in two zones fed by one header. The 32-inch-high by 60- inch-wide units store 8.68 cubic feet per foot. The 22,000-square-foot system, installed under a parking lot behind a school, has 527,000 cubic feet of storage. The entire project took about 10 months, including a two-month suspension during winter.