Interested in Cleaning?

Get Cleaning articles, news and videos right in your inbox! Sign up now.

Cleaning + Get AlertsPipe bursting and cured-in-place pipe lining are proven methods for renewing aging and deteriorated pipes. Here are several systems and tools that employ these technologies, along with excavation, pipe piercing and cutting, shoring, and horizontal directional drilling tools used to expose entry points and install new pipe.

Pipe Bursting Tools

Lateral pipe bursting machine

The Model PD-33 pipe bursting machine from Pow-r Mole Sales is a pipe replacement system featuring a long 24-inch stroke. Its nonslip cylinder-activated jaws are designed to prevent cable damage, while developing 60,000 pounds of pulling force at a rate of 6 feet per minute. It offers a cost-effective alternative to open-cut by reducing excavation up to 85 percent. Pipe bursting installs new pipe, giving the operator the ability to increase the pipe size when needed. The system is capable of bursting cast iron, concrete, HDPE, asbestos cement, PVC, ductile iron, orangeburg and clay pipe from 2 to 6 inches. It is a modular machine and can be disassembled into easily transported pieces with no single part weighing over 98 pounds. Modular construction enables the operator to access any location, including manholes. 800/344-6653; www.powrmole.com.

Pipe bursting puller

The Model 7000 pipe bursting puller from Poweram is designed to replace existing utilities by pulling pipe splitting and/or bursting tools through the old pipe and pulling a new pipe into the same space. The new pipe can be the same size or larger than the old pipe. With over 118,000 pounds of pulling force, it can split or burst up to 12-inch pipe and pull back up to 16-inch pipe in most soil conditions. The longest practical distance depends on the type of pipe to be replaced, terrain (grade changes), soil conditions, and repair couplings or splice pieces encountered. 715/537-9050; www.poweram.com.

Lateral pipe bursting machine

The lightweight lateral pipe bursting machine from RODDIE Inc. slides apart into two components of 50 and 60 pounds that can be lowered and reassembled by hand in the excavated pulling pit. In most cases this machine is powered and operated by a mini-excavator or bobcat tractor. It is capable of a 30- to 50-ton pulling force and can be used in 4-, 6- and 8-inch sewer laterals, but can also replace 1- to 4-inch water services. 888/406-3821; www.pipeburstingamerica.com.

Pipe bursting system

The UnderTaker from Spartan Tool replaces existing sewer laterals with new, seamless, high-flow high-density polyethylene pipe from 2 to 6 inches in diameter. It sets up quickly without any tools, and handles up to three 45-degree bends in the existing pipe. No component weighs over 70 pounds, so it’s easy to position. All is done with minimal disruption to the yard or business. 800/435-3866; www.spartantool.com.

Lateral bursting power pack

The Hi-Flow 13HP from TRIC Tools Inc. is a lightweight power pack geared to the lateral bursting market, with greatly increased flow (tool speed) at higher working pressure (tool power). Features include a Honda GX390 13 hp engine, maximum fluid flow of 4 gpm, a maximum hydraulic pressure of 5,000 psi and a 10-gallon hydraulic fluid reservoir. It comes with a folding handle, folding pick-point frame bracket, removable hoses (25 feet of 1/2-inch I.D.), and heavy-duty pendant remote control. 888/883-8742; www.trictools.com.

Tension winch

The TT Technologies 3-ton Grundowinch hydrostatic constant-tension winch is suited for underground utility applications including pipe bursting, underground cable pulling, sliplining, pipe pulling and swage lining. It features protective cable storage and is available with an air-cooled diesel or gas engine, as well as an adjustable boom. The constant-tension design means any cable slack is immediately sensed and quickly taken up automatically. Features include single-lever tension control (no gears to engage), power-assisted winch line feed and winch controls located at the rear of the unit to provide a safe view of the job while operating. It can pull up to 3,280 feet of 3/8-inch cable at speeds of up to 160 feet per minute. 630/851-8200; www.tttechnologies.com.

CIPP

Centrifugally cast liner

The CentriPipe pipe lining system from AP/M Permaform provides a cost-effective, no dig solution for structural lining of culverts using a bidirectional spincaster to centrifugally compact a precision liner at the best design thickness for the size, shape and conditions of deteriorated pipe. It inhibits rust and is highly resistant to abrasion. It waterproofs, seals, structurally reinforces and protects round, arched and elliptical pipe. It is professionally applied through a global network of certified applicators. 800/662-6465; www.centripipe.com.

Acrylamide grout

AV-100 acrylamide grout from Avanti International is a chemically reactive gel with the same viscosity as water that permeates anywhere water can travel with adjustable cure times from 5 seconds to plus or minus 10 hours. Used to rehabilitate and sustain sanitary collection systems, it eliminates infiltration in mainline joints, manholes, laterals and lateral connections. With a remote packer, it can be injected through the defect to the outside of the pipe structure to form a gel-soil matrix and long-lasting water barrier while stabilizing the soil in the sewer trench. 800/877-2570; www.avantigrout.com.

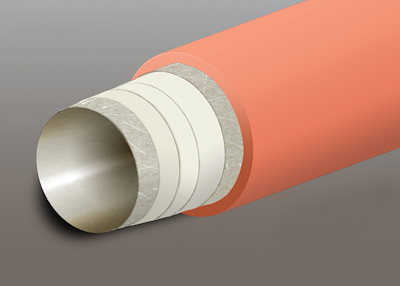

CIPP liner

AquaCure RP from Applied Felts Inc. combines fiberglass reinforcement with the company’s existing felt liner design and construction. It fully integrates and blends the properties of each, providing superior physical and mechanical properties while eliminating a learning curve because it installs just like the company’s nonreinforced liners. It is impregnated on the same roller beds, using the same vacuums, and can be installed with the same equipment and techniques. It stretches up to 10 percent to the existing pipe wall and delivers ideal resin saturation and retention properties. 276/656-1904; www.appliedfelts.com.

Internal joint seal system

The HydraTite internal pipe joint seal system from Cretex Specialty Products is trenchless remediation for the repair of pipe joints. It eliminates infiltration and exfiltration with a mechanical rubber seal (EPDM or nitrile) spanning the joint and steel retaining bands. Each seal is custom-made to ensure compliance with project specifications. The system can be used in almost any type of pipe (iron, concrete, clay or plastic) from 24 to 216 inches in diameter. Seals are available in 11-, 14- and 21-inch widths. Retaining bands are made from carbon steel, 304 stainless, 316L stainless or AL-6XN. The thickness of the bands varies with the size of the seal. A stainless steel backing plate can be added for added support when spanning voids in the pipe wall, such as the remediation of expansion joints, sealing off abandoned laterals or when repairing deteriorated joints. It can withstand the corrosive effects of hydrogen sulfide. 800/345-3764; www.cretexseals.com.

Epoxy resin lining

DURAPOX epoxy resin from Formadrain can be relied on for 60 days open time. That much work time means no liners lost over time restraints or unforeseen difficulties. The crew can focus on their work without stress. Liners can be shipped pre-wet. The system is a steam-cured pull-in-place lining used for laterals, spot repairs, industrial process pipes and LMC Lateral-Main-Connections. Pipe diameters range from 2 to 48 inches. 888/337-6764; www.formadrain.com.

Composite inversion drums

HydraLiner composite inversion drums from HammerHead Trenchless Equipment are lightweight, high-capacity inversion drums that allow technicians to use steam, hot water or ambient temperature to cure with one drum. They withstand the higher temperatures needed for steam curing. They are easily maintained, corrosion free and are seamless, eliminating a common failure point in other drums. Three drum sizes are available — the Mini-Hydra, Hydra and the Super-Hydra. 800/331-6653; www.hammerheadtrenchless.com.

Point repair system

The Infrastructure Point Repair System from Infrastructure Repair Systems is a no-dig system to spot repair any size pipe with no interruption of service. An epoxy-impregnated fiberglass and felt liner is wrapped and secured on a bladder, then inserted through the manhole and pulled to the leaking joint, pipe crack, or missing piece of pipe location. This no-shrink, corrosion-resistant repair will prevent infiltration and exfiltration, and can be used as a seal at the end of a lining system or as a presealer because it can be applied over active inflow. It is available for 3- to 48-inch-plus pipe diameter in lengths of 15 or more feet in four liner thickness options. 877/327-4216; www.irsi.net.

Structural lining system

EcoCast from Inland Pipe Rehabilitation is an environmentally friendly, precision-applied, centrifugally cast structural lining system that combines the most advanced application equipment with a custom formulated geopolymer for consistent application and long-term performance. It will successfully restore concrete, brick or corrugated metal storm and sewer pipes, and noncircular infrastructure. It is a particularly cost-effective solution for large-diameter pipe sections starting at 36 inches. Applications include storm drainage culvert renewal, manholes, wet wells, junction boxes, DOT and airport projects. 281/362-1131; www.teamipr.com.

CIPP renewal service

Inliner Technologies provides CIPP renewal solutions for deteriorating pipes and culverts ranging in diameter from 4 to 120 inches. Licensees are contracted by municipalities and industrial companies to renew storm, waste and process sewer piping that have been damaged by corrosion and/or structural deterioration. The company has installed over 18 million feet of pipe lining in the U.S. and Canada. With five licensees and approximately 400 employed within the Inliner network, the company’s technology has been utilized to perform pipe renewal projects in the U.S. and Canada since 1989. In-house tube manufacturing capabilities and an extensive network allow for competitive pricing with short lead times. 812/723-0704; www.inliner.com.

Main and lateral CIPP connection liner

The T-Liner from LMK Technologies is a one-piece homogenous main and lateral CIPP connection liner that is ASTM F2561 compliant. It has a uniform wall thickness and incorporates compressible lining material at the upstream and downstream ends, creating a smooth, tapered transition to the host pipe. Both the mainline and lateral sections are formed as a structural cylinder that renews 18 inches and 360 degrees of the mainline and extends up the lateral pipe as one continuous lining. Combining it with Insignia compression gasket-sealing technology provides a verifiable nonleaking system. These compression gaskets are embedded between the host pipe and the liner and are compatible with all pipe types including polyethylene. A permanent Lateral Identification Indicia is placed on the mainline lining, which includes the building address and other pertinent information regarding the raw materials and other pertinent manufacturing details. 815/433-1275; www.lmktechnologies.com.

Grouting packer

Test and Seal Grouting Packers from Logiball Inc. are used by specialty contractors and municipalities to stop infiltration at lateral connections and in lateral joints from the mainline sewer access to as far as 30 feet from the mainline. Chemical grout is pumped through the packer and forced out through existing pipe defects to seal and stabilize the soil around the injection points, preventing washout of backfill into the sewer and sealing off infiltration. 800/246-5988; www.logiball.com.

Flexible CIPP liner

The flexible CIPP liner from MaxLiner USA can work in up to 90 degree bends and handle diameter changes from 4 to 6 inches. The company’s CIPP system has received code compliancy from the International Code Council (ICC-ES). 276/656-1225; www.maxlinerusa.com.

CIPP lateral liner

MTube CIPP lateral liner from MTC is flexible, easy to invert and ideal for rehabilitating gravity-fed pipelines. The butted ends of the felt are sewn together to produce a smooth, uniform pipe wall around the circumference of the tube. A heat-bonded coating is then extruded over the seam to create a permanent connection at the butt-end seam joint. They are available in 6-, 8-, 10- and 12-inch diameters. 662/978-7797; www.mtubeonline.com.

Continuous inversion system

The Top Gun continuous inversion system from Perma-Liner Industries allows the CIPP liner tube to invert utilizing low air pressure. The liner inverts continuously without the need for above-ground water column towers, tall scaffold or the need for excess water in order to invert the CIPP liner. It allows the liner to invert easily and consistently without having to stop and start throughout the inversion installation. Most installs take less than 10 minutes, based on 500 feet of CIPP inversion from manhole to manhole. During the installation, no pressure is lost in the inverted liner. The liner is fully inflated at all times and held tightly against the existing pipe. Units range in different sizes to accommodate 6- to 36-inch diameters. 866/336-2568; www.perma-liner.com.

Lateral connection seals

The Interfit CIP lateral sealing system from Quadex/Interfit rehabilitates and seals lateral connections to lined sewer mains, eliminating infiltration and root intrusion. Depending on lateral defects/bends, the system extends from 1 to 20 inches into the lateral, sealing three critical problem areas — the annular space between a main liner and the host pipe, the lateral connection and the first joint. It includes a “full main wrap” (360 degrees) one-piece CIP fiberglass sock in the main that helps anchor the lateral portion of the sock. By using 25 to 30 psi inflation pressure, the nonshrinking resin attains superior migration into pipe defects, which yields superior mechanical adhesion and long-term performance. 870/688-7100; www.interfitusa.com.

Sewer lateral lining system

Quik Lining Systems is an advanced CIPP sewer lateral lining system that simplifies the process, giving the operator a lower cost per foot of lined pipe. It is lightweight, and a single operator can complete a job in about four hours. It gives crews the ability to install up to 8 or more lines per day. The unit can be operated from rooftops, basements or the street. The system’s design eliminates multiple handlings of materials and can line pipe at over 100 linear feet per minute. 714/296-5262; www.quiklining.com.

Life-extending lining system

The Raven 405 Series from Raven Lining Systems provides long-term performance in harsh, damp wastewater environments. Its 100 percent solids, zero VOC polymers demonstrate superior adhesion, low porosity and high chemical and abrasion resistance. It is a proven solution to stop recurring inflow and infiltration, featuring ultra-high build properties that make it ideal for overhead and vertical application. It is used on new concrete to protect against corrosion and extend the life of the structure, and can be used on old deteriorated structures such as brick, concrete or steel through a network of certified applicators. 800/324-2810; www.ravenlining.com.

Pipe transition lining

DrainPlus Liner from Trelleborg Pipe Seals Milford Inc. are comprised of a polyester needle fleece with a TPU coating designed to overcome lateral pipes with multiple bends and pipe diameter transitions and reduced wall thickness when the liner covers a change in internal diameter. They have great flexibility and are able to negotiate multiple 90 degree bends with minimal wrinkles. They are also designed to bridge transitions in pipe diameter up to two dimensions while retaining the minimum required wall thickness in the larger size pipe section. The TPU coating allows high-temperature resistance, and when used in combination with epoxy resins can be steam cured, allowing fast processing time. 800/626-2180; www.trelleborg.com/npc.

Controlled Water Pressure Inversion Unit

The Controlled Water Pressure (CWP) Inversion Unit from TRY TEK Machine Works Inc. installs 6- to 18-inch CIPP liner from manhole to manhole. With water’s superior heat retention, groundwater infiltration into host pipe is less likely to prematurely cool the liner causing incomplete curing and lifts. Incompressible water reacts instantly when unit is jogged, resulting in easier navigation of bends and irregularities. The liner remains constantly inflated from inversion through curing, eliminating host-pipe damage caused by multiple inflations. It can operate in places not accessible to high scaffolds or lift trucks. 717/428-1477; www.trytek.com.

Pipe Fusion

Pipe fusion machine

The McElroy Manufacturing Super 28 is capable of fusing 2-inch IPS to 8-inch DIPS polyethylene pipe. The machine features a diesel-powered, 28-fusion carriage on a TracStar 412/618 chassis. The configuration allows contractors to have a diesel-powered fusion machine on job sites where gasoline is unavailable or not allowed. It can be ordered as a combination unit that allows fusion of branch saddles with a maximum base diameter of 9.63 inches onto any size pipe main. It comes standard with a facer, heater, insulated heater stand and lifting assembly. 918/836-8611; www.mcelroy.com/fusion.

Underground Piercing Tools

Portable piercing tool

The BigShot underground pneumatic piercing tool from Footage Tools Inc. can be run with a small portable air compressor that delivers up to 75 cfm and 110 psi. New service lines can be pulled in behind it during the bore, or by reversing the tool with the service line attached to the nose pin. It can bore holes from 2 up to 5.5 inches to allow contractors to install a variety of pipe up to 4 inches in diameter. This method results in time and cost savings, along with reduced disruption to property. 888/737-3668; www.footagetools.com.

Moving-head pneumatic piercing tool

The Vermeer Hole Hammer pneumatic piercing tool features a moving-head design that provides full striking force of the piston to the head of the tool, pulverizing stones into the surrounding soil. The residual energy generated is used to help the tool body travel through the compacted bore path. This results in more accuracy and reduced tool deflection in tough soil conditions. It also incorporates a mechanical reset for the head assembly, helping ensure each blow delivered compacts soil in front of the tool to increase production and accuracy. Because it features a mechanical spring reset design, the head fits tightly to the body of the tool, resulting in an easy and smooth-starting tool. A ribbed tool body provides additional tool grip for traction in loose soils, helping achieve forward impact on each blow. It is available in 2-, 2 1/2- and 3-inch sizes. 888/837-6337; www.vermeer.com.

Horizontal Directional Drilling

Mid-size horizontal directional drill

Designed for the underground utility contractor, the JT25 HDD from Ditch Witch offers 27,000 pounds of thrust and pullback, a rotational drive with 4,000 foot-pounds of torque, and quiet drill operation. It is ideal for installing utility pipe and cables of up to 12 inches in diameter at lengths of up to 500 feet. It features a 130 hp, Tier 4i Cummins diesel engine. 800/654-6481; www.ditchwitch.com.

Directional drilling pipe

Directional drilling pipe from Underground Tools, Inc. fits all drill rig sizes from mini through maxi. It is made from high-quality materials, with consideration given to precise threaded connections. Integral forged drill pipe and forged/inertia-welded pipe are available. In addition, HIWS drill stems Versions I and II are available through manufacturer-direct distribution. All products come with DirtSmart technical service. 866/488-3478; www.undergroundtools.com.

Excavation Equipment

Hydroexcavator

The HV56 hydroexcavator from GapVax is a multipurpose unit ideal for virtually any wet/dry vacuum project. It has a 15-cubic-yard debris body and water tank options from 350 to 1,200 gallons. Features include a positive displacement vacuum pump rated at 3,500 cfm with 28 inches Hg. The design prolongs the life of the filter bags and eliminates the threat of material entering the vacuum pump. Options include a cold-weather recirculation package, sludge pump, auger unloading system, body pressurization system, remote pendants and wireless remotes, high rail package, washdown system, stainless steel body and a high-dump option. 888/442-7829; www.gapvax.com.

Air-excavation tool

The Utility Air-Spade 4000 Series from Guardair Corporation harnesses the power of compressed air to safely uncover underground utility lines without harm. Its supersonic nozzle generates a laser-like jet that moves at twice the speed. It features a nonsparking brass nozzle and components, electrically insulated 4-foot barrel rated to 300 kV and a lightweight, ergonomic handle. The aluminum handle features a full-size grip opening to accommodate linesman’s gloves. A dead-man trigger ensures safe operation, and a trigger guard prevents accidental activation. A retractable stabilizer bar provides superior operator control. An integral pressure gauge ensures optimal digging performance. 800/482-7324; www.air-spade.com.

Combination jet/vac truck

The Aquatech F-10 from Hi-Vac features a front-mounted reel designed by Aquatech. The 180-degree rotating front-mounted reel facilitates easy unit placement. Reel capacity is designed and engineered for up to 800 feet of 1-inch hose. The top-loading boom powers up and down and extends to 26 feet from the pivot point. The single-engine drive dramatically decreases fuel consumption, maintenance expense, weight on the chassis and the initial chassis price. The water pump consists of a continuous flow, triplex reciprocating design and is rated up to 80 gpm at 2,000 psi. An optional unloader valve allows for complete control of water flow and pressure independent of the vacuum power. Tanks are constructed of high-strength, UV stabilized polyethylene, with optional fixed internal baffled aluminum tanks. 800/752-2400; www.aquatechinc.com.

Construction-class crawler excavator

The 86,200-pound R380LC-9A construction-class crawler excavator from Hyundai Construction Equipment Americas is powered with a low-emission, low-noise, 290 hp Cummins Interim Tier 4/Stage IIIB QSB6.7 engine. Complimented by Cummins’ VGT Turbocharger, the airflow boost continuously varies to precisely match engine rpm and load demands. It comes with a redesigned hydraulic system that provides super-fine touch and improved controllability. It features the Hi-mate Remote Management System, which allows operators and dealer service personnel to access vital service and diagnostic information from anywhere with internet access. It boasts a bucket breakout force of 49,300 pounds, a maximum dig depth of 27 feet, and a 1.88- to 3.03-cubic-yard bucket. 877/509-2254; www.hceamericas.com.

Mini-excavator

TMX mini-excavators from Innovative Equipment feature a quick-hitch system that can be hooked behind a standard 1/2-ton pickup, van or light-duty tow vehicle. They eliminate tracks by utilizing zero-turn technology for access to tight locations and lawns. Weighing only 2,941 pounds, they feature an 8-foot digging depth and 6,600-pound digging force. The unit features a 7-foot-2-inch loading height with a swing radius of 140 degrees, allowing access next to walls and other obstructions. An auxiliary hydraulic tool circuit has the ability to power hydraulic tools including jackhammers, pumps and saws. 888/359-3002; www.iequipt.com.

Hydroexcavating tool

The Soil Surgeon hydroexcavating tool from The Soil Surgeon Inc. is designed to fit any sewer combination truck equipped with a telescopic 6- or 8-inch boom. The tool has a 1-inch water connection. The operator controls water pressure and power with truck controls. Features include 6-foot Tuff Tube with handles fabricated to the tube to guide the unit down for potholing or side to side for trenching. Six jets boring inward cut the soil, while six jets boring outward bring the tube down. Bumpers on the bottom protect the jets and lines the tool might contact. 949/363-1401; www.soilsurgeoninc.com.

Combination vacuum truck

The Mud Dog 1600 vacuum/hydroexcavator combo from Super Products features a 16-cubic-yard debris body, standard 1,500-gallon water capacity and a rear-mounted boom that offers 335-degree rotation, 27-foot reach and upward/downward pivot that enables operators to achieve greater work area access and deeper digging without the need to halt production to reposition the truck. It can deliver up to 18 gpm of flow and 3,000 psi of pressure, while its 8-inch positive displacement vacuum system provides airflow up to 5,800 cfm and 28 inches of vacuum to ensure the thorough removal of a wide variety of materials. An ejector plate system smoothly pushes the load out of the collector body and into the disposal site. It has the ability to raise and tilt its collector body to unload into disposal areas with barriers or berms. 800/837-9711; www.muddogeasy.com.

Hydrovac unit

The F4 hydrovac unit from Tornado Hydrovacs carries 13 cubic yards of mud and more than 2,000 gallons of freshwater. Components include a water tank from which you excavate, a mud tank in which the excavated spoils are held, a water pump, a boiler to heat the water and a positive displacement vacuum blower to pull the spoils to the tank via a boom. 877/340-8141; www.tornadotrucks.com.

Excavation unit

The X-Cavator from Vac-Con is available in configurations from 5- to 16-cubic-yard capacities, with hydrostatically driven three-stage centrifugal compressors. A variety of hydrostatically or mechanically driven positive-displacement blowers up to 28-inches Hg are also available. It can also be configured with dual positive-displacement blowers with airflow up to 7,000 cfm. Low-volume, high-pressure water systems with up to 4,000 psi are available with cross-linked polyethylene water storage tanks with up to 1,500 gallons of capacity. It is available with a Power Flex Boom that extends up to 28.5 feet from the machine and rotates up to 315 degrees. The boom articulates up to 110 degrees and will lift up to 34 feet into the air. Booms are available with up to a 10-foot extension, and 8- and 10-inch tube diameter. 904/284-4200; www.vac-con.com.

Dumping hydroexcavator

The Vacall AllExcavate hydroexcavation truck features a high-dump option that allows the operator to use a wireless remote control to raise the debris tank as much as 76 inches above ground level, and then shift the tank horizontally 21 inches beyond the rear bumper. That enables it to dump debris into roll-off containers, typically with an edge that’s 60 inches above ground level. It uses just one engine for mobility and to generate water flow at 10 to 25 gpm and pressures up to 3,000 psi. Used in combination with strong vacuum, it can loosen and remove dirt, rocks and other material from around utility lines and foundations. Standard and optional debris bodies and water tanks are available. The AllSmartFlow CANbus intelligent control system is standard, monitoring water usage and minimizing downtime for water tank refills. 800/382-8302; www.vacallindustries.com.

Pipe Cutters

Reinstatement cutter

The Dominator 430 reinstatement cutter from Bowman Tool Company & Systems is designed to operate in 6- to 30-inch relined pipe. Its streamlined design features no external air tube and is stabile in the pipe due to its 72-pound construction from a solid billet of stainless steel. The head assembly incorporates a pinionless, quick-change design and only one adjustable gib. Lateral reinstatement is achieved with the 0.8 or 1.2 hp cross-flow air motor, but for optimum cutting performance in 8-inch and larger pipe, the 2.5 hp geared air motor can decrease reinstatement time by approximately 80 percent. It can be disassembled and reassembled in approximately 30 minutes due to its eight-moving-parts design. All the electric motors are isolated at the end of the cutter in a watertight chamber, eliminating water-damaged motors and allowing for easy and quick access. It is manufactured from temper-hardened stainless steel and bronze. 717/432-1403; www.bowmantool.com.

Pipe-milling robot

HydroCut 150 and 200 self-propelled milling robots from IBG Hydro-Tech feature milling arms equipped with a camera (480 TV lines) that can rotate 360 degrees. They also feature improved high-resolution LED lighting, allowing users to gain a better perspective on precise work. It has a hydraulic feed-through for high-pressure water up to 3,600 psi with a slip ring on the milling arm that increases mobility, making it swiveling endless. www.ibg-hydro-tech.de.

Pipe-cutting chainsaw

The Utility chainsaw from ICS - PowerGrit addresses operator safety with grinding technology that eliminates rotational kickback and offers improved operator positioning when cutting pipe. Utilized by public and private water and wastewater departments worldwide, it is designed to cut a variety of materials from ductile iron to plastic pipe with far less excavation. The ability to cut up to 24-inch pipe without changing position reduces the difficulty of the job. 800/797-4748; www.powergrit.com.

Reinstatement and drain cleaning lateral cutter

The Maxi Miller lateral cutter and two-step drain cleaning system from Picote Oy Ltd features a range of 75 feet, which can be expanded another 32 feet with a connector. Its Servo motor allows an efficient removal of hard materials from 3- to 10-inch drains and sewers with stainless steel grinding chains. It also powers Picote’s Smart Cutter and Twister lateral cutters, enabling a quick reinstatement of connections. The motor features an adjusted torque limiter and shaft protection. Its aluminum frame has powder coating frame protection, a two-way moving system, and stair glides to ease up or down stairs. 219/440-1404; www.picotesolutions.com.

Lateral cutter

The Micro Premium lateral cutter from Pipeline Renewal Technologies features a touch-screen interface, a large reservoir for flushing water, and easy connection/monitoring of supply air. In addition, the form factor of the reel broadens options for installing and transporting the system. Using remote-inflated air bladders, the arm of the cutter positions itself remotely by creeping and climbing; clamps itself for precise cutting in vertical or horizontal orientation; and feeds the cutting head a full 4 inches. Just 72 mm in diameter, the arm fits through small openings, and its articulation (400-degree rotation and 90-degree swivel) facilitates precision cutting, as well as maneuvering through 90-degree bends in 4-inch lines. Detachable operator controls consist of twin joysticks, a touch-screen control interface, full QWERTY keyboard and a 10-inch video display. 866/936-8476; www.pipelinert.com.

Shoring

Slide rail system

The Slide Rail Shoring System from American Shoring can be used in a number of configurations, including for the bore pits commonly used to bore under roadways, streams or other obstacles. The sheeting system can be used at depths up to 30 feet and is installed with an excavator with no need for special equipment. The system can also be equipped with a doghouse panel to accommodate the casing pipe. 800/407-4674; www.americanshoring.com.

Lightweight shoring system

The FlexShore shoring system from Pronal-USA Inc. is PE certified to be in compliance with OSHA Standard 29 CFR part 1926, subpart P. It is approved for type A, B and C60 soils at depths up to 6.5 feet. It is made of puncture-resistant material and is easy to handle at only 28 pounds. Its design allows two people to set up a trench box in under 10 minutes. It requires minimum storage space, and is flexible and adaptable to most types of excavations. 386/310-1558; www.pronal-usa.com.

Pneumatic shoring

Pneumatic shoring from Prospan Manufacturing Co. is designed to meet the OSHA excavation standard 29CFR 1926.650 that governs the safety of workers in trenches. It is an air-driven telescoping aluminum shoring device that delivers compressive forces to the trench wall preventing collapse. Made of anodized aluminum and stainless steel, it weighs 15 to 32 pounds and is available in four sizes spanning 21.5 to 105 inches. A variety of extensions and end attachments are available. 888/413-8100; www.prospanshoring.com.

Trench shoring system

The corrugated aluminum ultraSHORE trench shoring system from Safety Corporation of America features stackable panels that can be used horizontally or vertically for bury depths to 12 feet in Class C soils. Extra features include leg and wheel kits for OSHA regulations. Easily transported in a pickup, the system can be closed off on one or both ends with quick-release, spring-loaded end-closure panels. 800/746-7464; www.shoring.com.