Interested in Flow Control?

Get Flow Control articles, news and videos right in your inbox! Sign up now.

Flow Control + Get AlertsCity seeks solution to eliminate data capture errors

Problem: The city of Toronto sought to create and facilitate access to a complete asset inventory that would virtually eliminate all errors during the inspection data capture.

Solution: By choosing CTSpec Sewer, the city became aware of the complete inventory of sewer assets, including pipe and manhole conditions. The solution was rapidly adopted by the contractor responsible for the sewer asset inspections and ensuring continuity and accuracy throughout the chain of information — from the field data collection to its processing by city analysts and engineers. A single solution (covering asset inspection all the way through to report preparation) made it possible to provide a consistent, comprehensive approach to information management.

Result: All of the city’s teams were able to increase their productivity because of the automated update of infrastructure conditions, the production of thematic maps, and the improvement of information sharing. Information was highly reliable, allowing analysts to focus their efforts on asset management and operational priorities. It is easy to produce specific reports on the condition of sewer systems and the need for inspection, maintenance, and repair operations. 888/965-8987; www.ctspec.com.

Ultrasonic water meters help city increase water revenue

Problem: The town of Dexter, New Mexico, had old positive displacement meters. The moving parts inside the meters had worn over time, and the city was losing revenue for water they were distributing to customers. Wear and tear caused the discs to rotate less and therefore measure less water volume.

Solution: The town replaced their meters with Kamstrup Water Metering ultrasonic water meters. Ultrasonic meters have no moving parts, which benefits water systems in two ways: they measure lower flows and do not lose accuracy over time.

Result: When comparing usage between November 2015 and 2016, the town of Dexter billed 1 million more gallons with the new ultrasonic water meters. “We are excited [about] the long-term benefits [this] will provide to our water department and our community,” says Yolanda Alvarez, utility clerk for town of Dexter. 440/835-6716; www.kamstrup.com.

Automatic flushing system restores chlorine residual

Problem: Halifax Water (Halifax, Nova Scotia) provides potable water, wastewater and stormwater services to 86,000 customers. When a local car wash shut down, its water connection needed to be closed. As a result, there was nonmovement through this section of the main, which contributed to a decrease in chlorine residual. To ensure water safety levels were met, weekly flushing of a nearby hydrant was required, which was costly, time consuming, and contributed to nonrevenue water loss.

Solution: The hydrant was replaced with a Hydro-Guard HG-4 LongNeck Sub-Surface Direct Discharge Unit from Mueller Co., housed in a natural-looking rock cover. It has the capability of flushing, dechlorinating and expelling the water into a storm sewer in an environmentally safe manner. After a series of tests to determine optimal location and flush times, Halifax Water staff easily programmed the ideal sequence to achieve the best results.

Result: Site visits have been reduced from eight to one per month, a savings of $14,700 annually. Water loss for flushing has decreased by 28 percent, and the optimal flushing schedule has resulted in steady chlorine residual levels. Aggregate costs have fallen from $42,000 to $24,750 within the past two years, a total savings of $17,250 after installation. 800/423-1323; www.muellercompany.com.

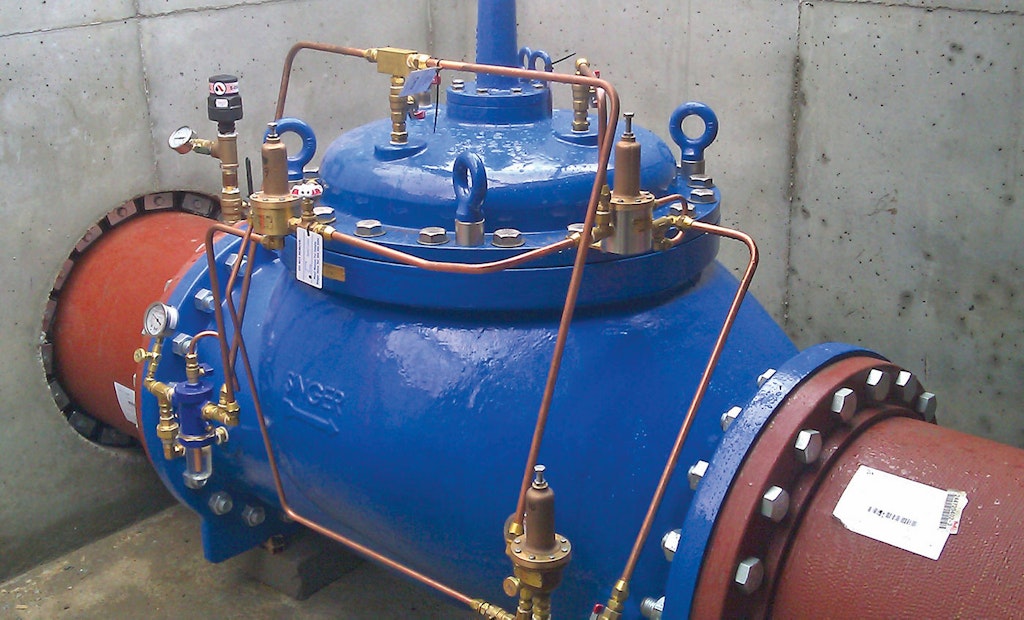

Control valve stops cavitation caused by varying summer and winter demand

Problem: The Hutchinson, Kansas, water plant distributes water through mixing butterfly valves that were designed for high summer demand. The low winter demand created inlet pressure variations from 90 to 50 psi while the outlet pressure was 10 psi. Consequently, there was severe cavitation and the valves were failing after just two years.

Solution: The simplest, most cost-effective solution was a pressure-reducing valve with anti-cavitation trim in front of the plant. In this case, the valve would take the main pressure drop while the mixing butterfly valves would be used for trimming the flow. They installed a 20-inch S106-PR-AC pressure-reducing valve from Singer because it has a single rolling diaphragm that provides smooth, steady and precise pressure control from maximum to virtually zero flow.

Result: Once the valve was put in place, the unbearable sound from cavitation was no longer present, and now there is consistent, reliable flow and pressure to deliver up to 10 mgd. Going forward, the city should no longer have to incur the costs of replacing the valves on an annual or biannual basis. 888/764-7858; www.singervalve.com.