Interested in Infrastructure?

Get Infrastructure articles, news and videos right in your inbox! Sign up now.

Infrastructure + Get AlertsThere are many kinds of flowmeters and different ways of installing them. It is now possible to install a flowmeter without cutting the pipe or even shutting down the line. The FPI Mag full-profile insertion flowmeter from McCrometer measures flow across the entire flow profile and is easy to install using a hot tap installation process.

“You can walk up to a pipe and, without shutting it down, do a hot tap and insert the sensor while the pipe is under pressure and water is still flowing,” says Joe Clements, applications engineer for the manufacturer. “It avoids shutting down the line, which is both inconvenient and expensive.”

Walk-around

There are two FPI Mag models; Model 394L measures bidirectional flow and Model 395L measures forward flow. The 394L has electrodes on both sides of the sensor and an automatic switch to match the direction of flow. The 395L has electrodes on only one side but indicates if flow is reversed.

The FPI Mag is custom-built for each installation and can be installed in pipes from 4 to 138 inches. “It is good for applications where there has never been a meter, or to replace a failed full bore meter,” Clements says. Non-operational full-bore meters can be left in place.

The sensor is made of stainless steel for structural integrity and is coated with an NSF-certified 3M fusion-bonded epoxy. The electrodes are on the surface of the sensor, while the electromagnets that create the magnetic field are inside the sensor. There are no holes in the sensor, which eliminates leaking, fouling or failing.

The number of electrodes depends on the length of the sensor. There are two electrode pairs on those from 4 to 8 inches long and a maximum of eight for sensors from 72 to 138 inches.

Because the FPI Mag has multiple electrodes across the length of the sensor, it provides an accurate calculation of the flow, according to Clements. Each electrode pair is positioned uniformly along the axis of the sensor, each measuring a cross-sectional area.

The FPI Mag is based on Faraday’s Law: A conductor (such as water) produces a voltage directly proportional to its velocity when moving through a magnetic field such as that produced by the electromagnetic coils inside the sensor.

Clements explains that there is variance in flow across a pipe diameter: “Water that is right next to the walls of the pipe isn’t moving much, and it progressively speeds up as it gets closer to the center, where you find the maximum velocity.”

Disturbances in the flow, such as an elbow, can make accurate metering difficult. A valve, even if open, leaves some disturbance in the pipe and can push the maximum velocity from the center to one side of the pipe.

The FPI Mag flowmeter can accurately measure the flow profile in such conditions because it measures several points across the pipe’s diameter.

The FPI Mag sensor is designed for water applications from 14 to 170 degrees F, and the electronic equipment is rated for environmental temperatures of -4 to 140 degrees F. The converter can run on AC or DC power, which must be specified when ordered, and is rated IP67 for dust protection and temporary immersion. The FPI Mag sensor is rated IP68 for submersion and measures water velocities from 0.3 to 20 feet per second.

The FPI Mag flowmeter is intended for use with clean water. While it will not clog from exposure to sand and grit, it is not appropriate for applications with solids such as paper or grass in the water. Those materials can wrap around the sensor and prevent the sensor from accurately measuring the flow.

Drinking water applications include measuring flow in distribution lines, wells, and pump and booster stations, for filter balancing and backwashing, and as dosing meters for UV disinfection. Wastewater applications include monitoring reclaimed water and effluent. The FPI Mag is also useful in industrial settings for metering chilled, cooling, and process control water.

Clements says customers often use the FPI Mag to help monitor distribution systems which can assist with accounting for water losses. “If you have two meters on a line, it can help determine if there are unknown leaks between the meters.”

Operation

By way of a PowerPoint presentation which provided a sequence of illustrations, Clements demonstrated the installation process for the FPI Mag flowmeter. Once the location is selected, a manhole is built around the pipe, if it is underground. The device can also be installed in an existing manhole or vault. On exposed pipes, the unit is simply installed.

The FPI Mag flowmeter consists of the sensor and a compression seal; there are no moving parts. The compression seal is installed on a 2-inch full-port ball valve or corporation stop. “We installed a 138-inch meter and two of us were able to pick it up, carry it to the location and do the installation,” says Clements. “It’s light enough to be handled easily.”

The process starts with welding or clamping a 2-inch nipple onto the pipe wall. A 2 inch full-port ball valve is then screwed into the nipple and the hot tap process is then completed on the wall of the pipe. The compression seal is attached and the FPI Mag pre-calibrated sensor is then inserted.

“As soon as you have the end of the sensor in the compression seal and engaged a couple of inches, you can open the valve without leaking any water,” says Clements. “You tighten the top plate with captive nuts onto stainless steel threaded rods and push the sensor through the port and into the pipe until you contact the far wall.”

The nuts are tightened another half inch. A spring on the top plate keeps the sensor firmly seated in the pipe and prevents it from being ejected by the pressure in the pipe, which can reach up to 250 psi.

The FPI Mag can be removed easily for cleaning and calibration checks while keeping the line in service. Removal is usually not necessary, although some communities require calibration checks of all meters periodically. McCrometer offers installation and startup services and certified factory calibration to accommodate such needs.

Once the meter is in place, the cable from the sensor carries the electronic signals to a converter that interprets and displays the information in the user’s preferred units (English or metric), typically gallons per minute or million gallons per day.

The electronic unit is housed in a die-cast aluminum enclosure that measures 6 inches square and 7 inches deep. The 4-20 mA output transmits data to a recorder, SCADA system, or control room display. Units are often installed in the field where no such data hookup is possible, and in such cases the display is checked manually.

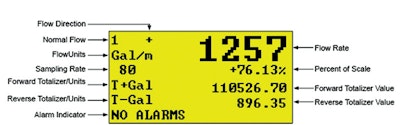

The FPI Mag uses the McCrometer “L Series” converter, which displays several real-time and total measurements, including:

• Flow rate

• Total flow (forward & reverse)

• Flow direction

• Flow speed

• Alarms (high and low flow rates, empty pipe, and other fault conditions)

Observer comments

The need for recording flow is increasing every year for regulatory compliance and performance improvements. The FPI Mag flowmeter is relatively easy and inexpensive to install compared to a full-bore meter, yet yields comparable data and accuracy.

Installing such a meter without getting wet or shutting down a line is an attractive feature and seems to be a straightforward process for any experienced technician.

Manufacturer comments

“There are other insertion flowmeters, but they are all single-point meters,” Clements says. “We’ve installed the FPI Mag flowmeters in less than an hour in some cases.”

Clements says installation costs can be reduced by 45 percent or more in large lines over installing a full-bore meter that may require excavating, cutting and removing a section of pipe and installing flanges.