Interested in Rehab/Relining?

Get Rehab/Relining articles, news and videos right in your inbox! Sign up now.

Rehab/Relining + Get AlertsMore than half the sewer lines in Great Neck, N.Y., are nearly a century old. But like a spry senior citizen who keeps trim by working out daily, they seem younger than they are.

The secret? “Constant vigilance,” as Harry Potter’s mentor and hunter of evil wizards Mad-Eye Moody might say. Or in the plainer words of Christopher Murphy, superintendent of the Great Neck Water Pollution Control District, “We have a very aggressive preventive maintenance program.”

For the last eight years, sewers in the district have been on a rigorous cleaning and inspection schedule. The program has cut sewer backups in the Long Island community. And that’s just one of several measures the district has taken to make sure its system is as clean and efficient as possible.

Getting on schedule

Located on the north shore of Long Island just east of the New York City borough of Queens, the district serves 15,000 residents of five Nassau County villages, along with some unincorporated territories.

The area is mostly residential, with a substantial number of restaurants and a few industrial customers. By 2014, the district will add another 10,000 residents, along with 19 miles of sewer line and five more pumping stations, from the village of Great Neck just north of the district’s existing boundaries. A treatment plant expansion will accommodate the additional load.

“When I got here in 2003, we didn’t really have any kind of formalized schedule for maintenance,” Murphy says. “You can’t run a 45-mile sewer system and five pump stations and not have some sort of organized system.”

A stickler for order and recordkeeping, he decided to change that. So starting the next year, the district divided the system into 72 zones, each to undergo routine maintenance every nine months. Within a few years, the results were dramatic.

“We saw the amount of problems basically dwindle to nothing,” Murphy says. “When I first got here we were averaging a backup maybe once a month. Now we’ve had one in the last three years. We’re pretty proud of that.”

With just nine employees, the district keeps its crews busy year-round. At maintenance time, crews jet out the designated sewer lines using a Vactor 2100 combination truck, purchased in 2008. Crews also inspect the manhole covers and manholes, including the bricks or block on the manhole walls. They check jetting debris for grease and grit and apply grease-cutting foam in lines where they find grease. And they do some community relations work for the district when residents gather to watch.

“We have very visual vehicles, and residents are always curious to see what our crews are doing,” Murphy says. Automated scheduling helps keep the maintenance program on track. Each month, the district generates an 11- by 17-inch booklet highlighting in yellow all the line segments due for maintenance. If crews don’t get to a zone in that particular month, it comes back on the next month’s list — this time highlighted in red, and red zones get first priority.

Ramping up TV

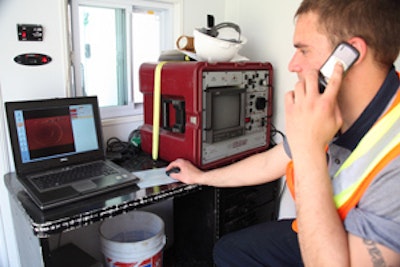

Along with systematic maintenance, the district became much more aggressive with CCTV inspection. In 2004 the district purchased a Saturn III camera and Badger wheeled transporter from Aries Industries. District employees have trained with Aries to handle routine repairs for the units, reducing downtime and expense.

The goal is to inspect the entire system on a two-year cycle, but when cleaning results are unusual, crews bring in the camera for a special look. Based on the results, they may change the line’s cleaning schedule from the standard nine months — more or less frequent cleanings depending on the line condition. “We’re fine-tuning each pipe,” Murphy says.

CCTV operators use ITpipes software, from Infrastructure Technologies to note pertinent findings. For example, they grade infiltration problems on a scale from 1 to 4 and highlight specific problems such as root intrusion or chronic grease and grit accumulation. Infiltration problems graded 2 or higher go on a list for repairs.

“We can plan not only for repairs that have to be done, but also for capital expenditures in the future,” Murphy says. “If I have an offset joint or a small hairline crack that isn’t an issue now, I’m not going to wait until it becomes an issue. I can plan in the next two years when I’m going to repair that, or put it in next year’s budget for replacement. Over time, we’ll be able to structure our capital repair plan right down to the tee because we now have full control of what gets done when it gets done. We’ll be a lot more efficient.”

Nozzle know-how

With its heavy reliance on jetting, Great Neck has assembled an arsenal of nozzles, mostly models from Enz USA. “One of the things we like about the Enz nozzles is that they have interchangeable ceramic tips,” says Murphy. “The ceramic is incredibly hard, so it lasts a long time, and as they start getting worn, we can just replace them.”

Changing nozzle tips also allows crews to deliver adequate pressure to the pipe wall even when using the district’s older 1995 jetting truck that delivers 40 gpm. “So it gives us a lot of flexibility,” Murphy says.

For pump station wet wells and manholes, the district relies on the RGS Radial Rotating Nozzle. Instead of shooting water out the end, it sprays circumferentially. As it is lowered into the manhole, it cleans the sides from top to bottom. “It puts all of its force to the side,” Murphy says. “You can stand there and hold the hose and it just spins and shoots out sideways. We lower that down into the manhole and strip all the debris off.”

A similar standby model is the Bulldog, a spinning nozzle that jets water straight out the sides as well as to the front and back. “If we have any recent grease accumulation, that will knock it right off,” says Murphy.

Another, the Chain Scraper Nozzle, includes a series of interchangeable chains and cutting cables that spin during operation. It can be used to ream out grease or cut up invading roots. A special series of retractable skids help center the nozzle even in pipes that are not uniformly round.

The Ejector nozzle works a bit like the motor in a jet-style personal watercraft. It’s especially useful in large lines that may be partly full, such as 24- to 30-inch trunk lines. The design allows the unit to use water already in the line along with the jetter’s water.

“An 80 gpm truck with this nozzle can have a flushing capacity of basically 200 to 300 gpm,” says Murphy. “So we can get everything out of that pipe and apply the same amount of pressure as if we were doing just a regular pipe.”

Then there is The Flounder. Unlike the typical cylindrical nozzle, this unit is flat, like the fish it’s named for. “It rides along the bottom of the pipe and puts the majority of its force at an angle to the bottom of the pipe,” says Murphy. “You can plow a tremendous amount of grit as you’re pulling back.”

This model is especially useful in irregular pipe where grit and other debris accumulate in dips at the bottom. And with the combination truck’s vacuum hose at hand, “we’re plowing the grit back with the nozzle and then sucking it out as soon as we get it.”

Manhole rehab

More than 50 percent of the lines in the existing Great Neck system date back to before 1915 and are made of clay pipe with joints every three feet. Manholes date back to the 1930s and before and have brick chimneys. Though well made, they have exceeded their life expectancy. And that’s where one newly acquired tool comes in.

Great Neck bought a trailer-mounted manhole rehabilitation unit from AP/M PERMAFORM that uses a centrifugal mechanism to spray structural mortar or grout on the inside of a manhole as it descends from the street level to the bottom.

“We’ll be able to coat the inside of a manhole from the street level,” says Murphy. That will reduce the length of time needed for confined-space entry. “When we’re done with the walls, we’ll go down and trowel the bottom of the manhole and the top by the frame, and we’ll have a watertight, structurally rehabbed manhole.”

Murphy expects to be able to rehabilitate a manhole for much less than the cost of hiring a contractor at $500 to $1,000 per manhole. “We have a couple thousand manholes, so that can be quite a savings,” he says.

Great Neck also plans to acquire its own cured-in-place pipe lining system. Murphy sees huge savings there, too: Instead of paying $50 to $90 a foot for repairs, “we’re going to be buying the liner for considerably less.”

UV curing

Once the system is on hand, Murphy plans to schedule the worst lines — the ones crews have given an I&I Grade 4 — for immediate lining. Lines given Grade 3 and 2 will be scheduled next, followed by those in the heaviest groundwater areas, “where we know that if we have a break and we have to dig, it’s going to be an expensive repair,” Murphy says. Deep lines 20 to 30 feet down will be flagged after that.

For its CIPP technology, the district chose fiberglass liners impregnated with resin and cured using UV light (Reline America).

For Murphy, the sewer business runs in the family. After a career with the Long Island Water Authority years ago, his father retired to Maine, only to wind up working again as superintendent for a water and sewer district there. Murphy learned the science and math of the business at his dad’s side, took training and got a license in Maine, then moved back to Long Island, working a variety of jobs in the field, including as a consultant.

He also got a college degree in business management. In running the district, he focuses on finding savings wherever he can and offering as much information as possible to ratepayers.

“We want people to know where their money’s going,” he says. “We try to run this district as we would a business. There’s a lot of ways we can trim costs and show people where their money’s going. That will make them confident in what’s going on.”