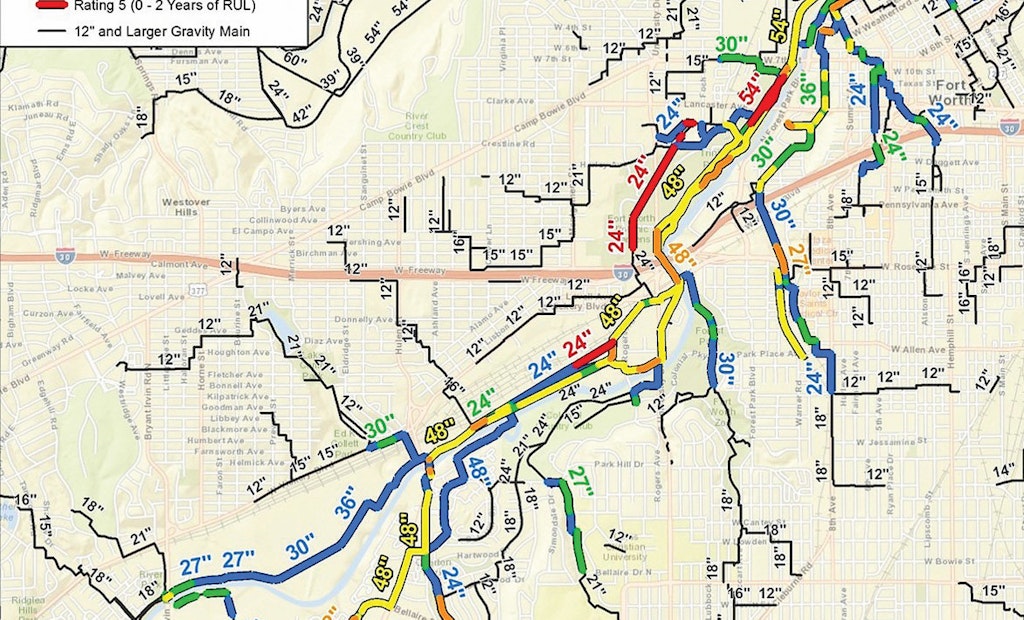

Inspected wall loss and remaining wall thickness are used to assign pipe segment condition scores, which are referred to as Remaining Useful Life scores. The scores can then be used to prioritize actions.

In the first four years after implementing its Interceptor Condition Assessment Program, the Fort Worth Water Department prevented an estimated 59 sanitary sewer overflows and saved $3.6 million to $6.6 million.

For more than a decade, Fort Worth, Texas, has been recognized as the fastest-growing metropolitan area in the nation, resulting in a great deal of resources being dedicated toward building new wastewater infrastructure to accommodate the rapidly expanding population. At the same time, the Fort Worth Water Department recognized the importance of serving and maintaining the existing infrastructure of its wastewater collections system, which consists of more than 262 miles of large-diameter sewer lines 24 inches in diameter and greater. The cost for the city to clean these lines for inspection is $2 million, which can be a strain on limited resources.

In an effort to find a more efficient, cost-effective, and accurate way to determine the condition of these vital sewer interceptors and develop recommendations for a long-term capital improvement plan, the city initiated an ICAP. It began in October 2010 and is currently planned to have a duration of eight years. The ICAP project team is using results from the 2012 Wastewater Collection System Master Plan, as well as input from the field operations group to prioritize sewer interceptors for inspection under the ICAP.

A better picture

The first step of ICAP is the pre-engineering inspection process to create a map of the infrastructure. During this stage, the team walks the lines in the field and conducts thorough research to better understand the infrastructure, such as the size and composition of lines and locations of manholes.

Once a map is created, the field condition assessment can begin. This process involves the deployment of three types of technology: high-definition TV inspection, sonar inspection and 3-D laser inspection.

• HD TV inspection is the most advanced method for capturing video images. Once the HD TV inspection data is collected, it can be viewed using conventional digital video viewing software.

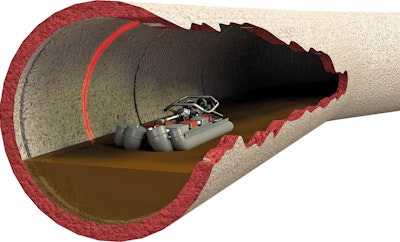

• Sonar inspection is used to inspect the pipe below the water level flow line. The device sends a sonar signal and measures the time required for the signal to return. The technology then creates an image of the pipe below the water surface and identifies accumulation of debris, deformation due to deflection in the pipe, breaks or other defects. As the sonar travels along the pipe, the data points are aggregated to create a 3-D model of the debris and pipe surface below the flow line.

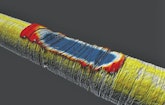

• 3-D laser inspection uses laser technology to create a 3-D model of the pipe wall above the water flow line. Similar to the sonar technology used below the water flow line, the laser sends a rotating beam of light around the pipe surface and measures the amount of time required for the light to bounce back. Using thousands of data slices along the length of the pipe, a 3-D model of the pipe wall is created.

In the case of Fort Worth, the HD video camera, sonar and 3-D laser sensor technologies are all mounted together on the FlyEye System developed by RedZone Robotics. The rig is then pulled through the pipe segment on a pontoon float to collect data.

Once retrieved, the data is shared with the technology manufacturer to develop a 3-D model of the entire pipe length. Combined with the HD video, the result is a high-resolution visual picture of the pipe and a 3-D model of the pipe that is used for detailed condition analysis.

Testing thickness

One of the most useful pieces of data to be collected from the inspection is the pipe wall thickness, as this information helps determine the condition of the pipe and its anticipated life span. Pipe specification data establishes the original interior diameter of each pipe segment, which can be compared to inspection data measuring the amount of wall thickness loss. The difference between the inspected inside wall location and the original inside wall location is used to calculate the inspected wall loss.

The inspected wall loss or remaining wall thickness is used to assign pipe segment condition scores, which are referred to as Remaining Useful Life scores. These scores fall into one of five categories. The ICAP project team used the following condition scoring system for reinforced concrete pipe segments:

• Score 1: Material loss of 0 to 0.5 inches from original inside wall. Estimated Remaining Useful Life is 36 to 50 years.

• Score 2: Material loss of 0.5 inches to interior face of first row of reinforcement steel. Estimated Remaining Useful Life is 21 to 35 years.

• Score 3: Material loss from interior face of first row of reinforcement steel to half the distance to interior face of the second row of reinforcement steel. Estimated Remaining Useful Life is 11 to 20 years.

• Score 4: Material loss from half the distance to the interior face of the second row of reinforcement steel to the interior face of the second row of reinforcement steel. Estimated Remaining Useful Life is 3 to 10 years.

• Score 5: Interior face of second row of reinforcement steel to outer pipe wall surface. Estimated Remaining Useful Life is less than 2 years.

Pipe segments scoring a five are considered to be in imminent failure and are in need of emergency rehabilitation. Pipe segments scoring a four should be included in the next available design and construction projects release.

In addition to assigning a Remaining Useful Life score to each segment, the sonar inspection data enables Fort Worth to more effectively clean its pipes by focusing just on the portions of the interceptors that require cleaning. In the past, they would clean the entire interceptor due to the lack of available data. Utilizing the ICAP inspection data to limit cleaning to just the segments requiring attention has already saved the city $4.5 million in large-diameter cleaning cost to date.

Reaping benefits

The city of Fort Worth and the project team’s approach to wastewater system condition assessment achieved multiple benefits and provided a sustainable business process to inspect, score, and monitor critical major wastewater interceptors. In the first three years, Fort Worth was able to inspect 49 percent of the large-diameter lines.

The benefits of ICAP can be summarized into three areas:

1. Reduced capital improvements: The capital improvement plan was estimated to be reduced as a result of the ICAP by two primary means. The first was the ability to restore capacity through focused detailed cleaning and removal of large debris in multiple interceptors. The city’s InfoWorks CS hydraulic model (Innovyze) was reanalyzed in locations where significant debris was identified and removed from the wastewater interceptors to determine if CIP improvements can be deferred or downsized in the future. The second was the replacement of portions of sewer interceptor instead of the entire interceptor.

2. Reduced reactive maintenance and cleaning costs: Prior to the creation of the ICAP, the Fort Worth Water Department utilized the industry standards of “clean to inspect” to determine pipe condition and restore capacity. Cleaning under ICAP using the clean-to-inspect method was projected to cost $1.7 million. Utilizing the sonar data developed from the ICAP results, the Fort Worth Water Department was able to “inspect to clean” at a significant cost savings. Cleaning cost utilizing the inspect-to-clean method totaled under $400,000, which represents an approximate savings of $1.3 million over the traditional method. It is estimated that the ICAP methodology will result in a savings of $15.2 million in cleaning cost over the eight-year program.

3. Enhanced understanding and knowledge of asset status and life cycle: The ICAP field assessment findings linked backed to the city’s CMMS program, GIS, and hydraulic model, providing enhanced asset understanding to enable the city to prioritize replacement projects more effectively. ICAP field assessment findings provided the needed information to the engineering user group during development reviews and annual budget planning on business case justification for renewal/replacement projects. Remaining pipe wall thickness can now be monitored, allowing the city to get the most value out of its assets before replacing them.

Big savings

ICAP has replaced traditional practices and provides more accurate pipe condition assessments, leading to fewer overflows, identification of potential failures before they occur, reduced rainwater inflow and infiltration, maintenance schedules addressing critical needs first, and reduced impact from maintenance-related construction.

During the first four years of the eight-year program, the benefits are already paying off. The ability to limit interceptor cleaning to just the segments that are in need of service has saved the city $4.5 million in cleaning costs to date while the ability to determine the Remaining Useful Life of the pipes enables the city to better plan for its short-term and long-term capital improvement budgets.

As the process continues over the next four years, Fort Worth will gain an even better understanding of the condition of its wastewater system and will be able to focus its resources to sections where it will have the most impact.