Interested in Stormwater?

Get Stormwater articles, news and videos right in your inbox! Sign up now.

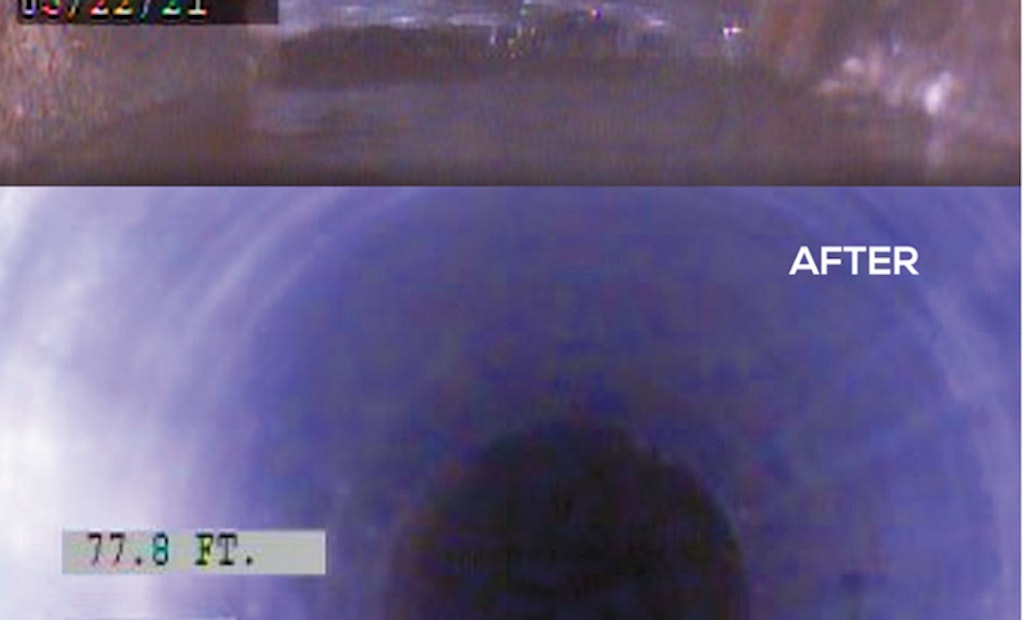

Stormwater + Get AlertsFailing culvert saved with trenchless point repair

Problem:

An Atlanta suburb was experiencing severe infiltration from a failing corrugated culvert, installed years before as a stream crossing. The exposed 8-inch culvert was used as a sewer line between two manholes and a retaining wall was built directly on top of it. Rusting over the years caused a couple dime-sized holes, allowing stream water to pour directly in. Traditional dig and replace methods required bypassing both the sewer and the stream to prevent sedimentation, in addition to demolishing and relocating the retaining wall. Contractor quotes were $90,000 and up, and would have required occupying adjacent homeowners’ yards for days with equipment and debris.

Solution:

EnviroWaste Services Group’s Atlanta branch installed an 8-inch-by-8-foot trenchless point repair, manufactured by Infrastructure Repair Systems. The repair was accomplished in a single, partial day from above the manholes with only foot traffic through homeowners’ properties. No bypassing of the sewer line or stream was required. EnviroWaste’s installation of the repair kit not only sealed the pipe from infiltration, but also created new structural capacity for the existing pipe.

Result:

By utilizing the kit, EnviroWaste Services Group was able to repair the culvert for less than a one-tenth of the cost of dig-and-replace methods. The infiltration was eliminated and the county avoided potential sanitary sewer overflows with virtually no stress for surrounding homeowners. 727-327-4216; www.irsi.net

Repairing a broken sewer line in northern New Jersey

Problem:

Service Professionals Inc. needed to provide a permanent solution to a broken sewer line in Teaneck, New Jersey, using relining technology. The area of Teaneck is in the northern part of the state at a higher elevation, and the soil is very rocky.

Solution:

The technicians — Rich Cooper, Bill Cobb and Thomas Irving — excavated the floor to expose the cast iron piping. They cut and removed a section of pipe to gain access to the line, which suffered from I&I. The first step was water jetting to flush out the line and remove the large amount of debris and roots. A camera inspection was performed to ensure everything was ready for the installation of the liner from Perma-Liner Industries. The technicians installed the new liner from the basement up to the main in the road. After the liner was inserted, a two-part resin was mixed and pushed into the felt liner. The liner was cured with steam and hardened as it cooled. This process results in a liner that is even stronger than PVC. After it cured, the technicians ran another camera inspection of the new line to make sure it was perfect. They then connected the new line to the existing back section while making an underground connection to install the new clean-out.

Result:

All this work was completed in just five hours, and has performed as advertised. 866-336-2568; www.waterlinerenewal.com/brand/pli

Sanitary district finds solution for I&I issues

Problem:

The Klamath Falls South Suburban Sanitary District in Oregon includes roughly 10 square miles and serves a population of approximately 25,000 people. It owns and maintains more than 100 miles of sewer pipe and more than 1,000 manholes. Most of the sewer mains were installed in the 1960s and ’70s and consist of asbestos cement pipe. Excessive I&I was causing overflows and unnecessarily increasing the treatment plant processing costs. They had been using flowmeters, but these were hard to install, hard to move around and were expensive.

Solution:

The district turned to the use of SmartCover sewer monitoring because the deployment was less invasive, as there is no confined-space entry for installation. Also, based on calibration against other flow systems, it delivered accuracy, trend analysis and modeling to hone-in on specific I&I issues, especially for a sub-basin.

Result:

For the relatively small staff, the SmartCover units helped with better targeting of available resources on addressing real issues of concern regarding I&I. By leveraging them, the district has been able to expand monitoring and enhance the granularity and detail of flow information that they receive. “Monitoring remote locations with SmartCover is key in our efforts to identify and combat I&I,” says Mike Fritschi, manager of the Klamath Falls South Suburban Sanitary District. 760-291-1980; www.smartcoversystems.com