Interested in Inspection?

Get Inspection articles, news and videos right in your inbox! Sign up now.

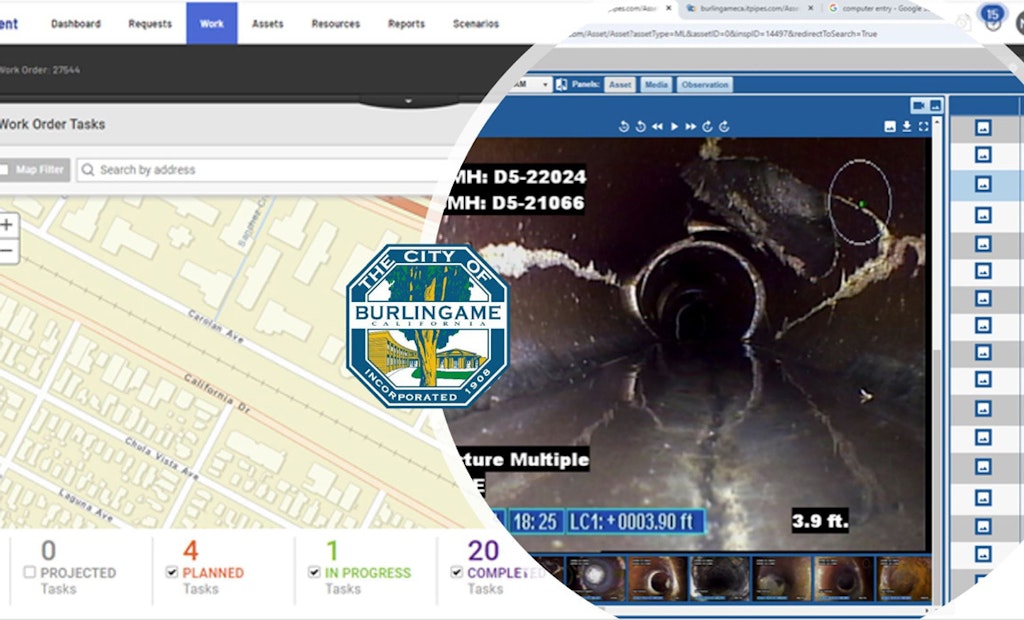

Inspection + Get AlertsCommunity employs inspection software to help prepare for storm

Problem:

With the picturesque and environmentally sensitive Big Thompson River running through its heart, the City of Loveland, Colorado, knew they had to take measures to protect it. That’s why in 2018, the city’s Public Works department prioritized storm sewer inspection and maintenance, bringing light to any issues underground.

Solution:

The city began by purchasing an IBAK CCTV inspection truck, then installing ITpipes Mobile, Sync, and Web. With an entire city worth of storm sewers to inspect, they knew their one crew had to be as efficient as possible. By integrating their Esri GIS, Cityworks Asset Management, and ITpipes inspection software, they have streamlined their workflow, allowing the crew to inspect around 10 or more pipes per day. These integrations allow the camera operator to select a pipe on the Esri map, which immediately opens the inspection for that asset in ITpipes, pre-populated with pertinent header data. Each night, all the pipe inspection data collected that day automatically uploads and syncs to the cloud. When that occurs, work orders are automatically created in Cityworks, allowing for labor, equipment and material costs to be tracked.

Result:

Thanks to this inspection data (plus a new combo truck), the city has strategically inspected and cleaned more pipe in this past year than the last five years combined. These efforts are allowing this rapidly expanding city to address issues such as upsizing undersized pipes, replacing deteriorated CMP, and building an accurate storm sewer model by locating missing/buried assets. With this undertaking, Loveland can show ratepayers massive quantifiable strides towards properly draining the city’s rainfall, all while protecting the Big Thompson River. 877-487-4737; www.itpipes.com

Software enhances crawler’s functions in pressurized pipe

Problem:

Contractor Action Pipeline of Arizona was tasked by Tucson Water to detect and repair a leak in a pressurized 36-inch pipeline.

Solution:

Given the inaccessibility of the deep water environment, the company used its Deep Trekker DT340 crawler specially designed for such tasks. Action Pipeline controls the unit using POSM Lite Software. “Without Lite, you can’t edit or add comments to the Deep Trekker footage ‘live.’ Instead, you must review the video and add observations after the inspection is complete. That takes longer and is less efficient,” says Andres Amado, Action Pipeline’s vice president of operations. “Lite is a streamlined, inexpensive software that removes options we didn’t need. And, most importantly, includes the ability to edit Deep Trekker video inspections ‘live.’”

Solution:

“We performed an internal investigation in the pressurized system. We installed an ink nozzle [onto the Deep Trekker unit] to seek and detect a leak ‘live’ thanks to POSM Lite,” says Amado. “We inserted the robot into the pressurized pipeline and located a defect in the mortar. We injected the ink and watched it get sucked out of the pipe to document the spot in real time.”

Result:

Because they paired Lite with their Deep Trekker, Andres says, “We were able to quickly and efficiently pinpoint the defect, dig it up and repair it.” 720-636-0532; www.posmsoftware.com

Software helps suburb prepare for population growth

Problem:

Like many municipalities with aging sewer infrastructure, the Village of Addison, Illinois, regularly faces I&I challenges, and two new subdivisions are expected to further strain its existing collections system. Previously, it was spending more than $50,000 per year on contracted sewer inspection projects in addition to an in-house crew of five.

Solution:

Now the sewer division’s assistant supervisor, Jim Rhoads, has WinCan VX sewer inspection software on his truck and can do the same work without contractors. Soon after they started using WinCan, the team began taking advantage of the software’s integrations with Lucity, finally connecting Addison’s sewer infrastructure data to a municipality-wide database of assets. “There is much more information attached to the pipe segments now,” says Rhoads. “Everything is catalogued, and not only are we using this data for inspection projects, we’re also using it for our high-velocity jetting.” Furthermore, using WinCan’s integration with Esri’s ArcGIS, Rhoads is able to plan work orders ahead of time, and inspect sewers more quickly and efficiently.

Result:

The integrations between WinCan, Lucity and Esri have allowed Rhoads to streamline his workflow to the point where he can now complete the majority of pipe inspections by himself. From building his work order in Lucity, to completing inspection in VX and conducting analysis in ArcGIS, having all the infrastructure data in one accessible place has streamlined his workflow. What’s more, Addison can now take on future I&I challenges with confidence, preparing its sewer team and system for the expected population growth. 877-626-8386; www.wincan.com