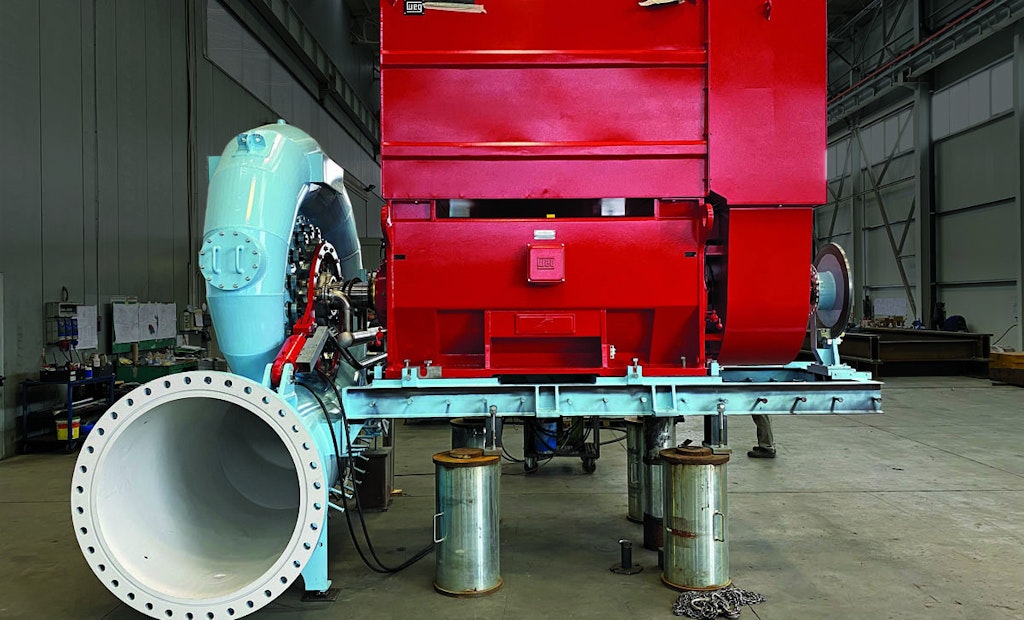

This 1.0 MW Gugler hydroturbine, along with a 0.5 MW unit, will be installed at Pueblo Water’s Whitlock Water Treatment Plant.

Interested in Flow Control?

Get Flow Control articles, news and videos right in your inbox! Sign up now.

Flow Control + Get AlertsHaving its main water supply at a high elevation has always been a mixed blessing for Pueblo Water.

There is no need to pump the water to the plant because it flows downhill, but it comes in at a much higher pressure than the treatment process can handle.

The solution for many years has been pressure relief valves, but now the utility, at the base of the Rocky Mountains, is looking to turn that pressure into electricity, installing two hydroturbines to capture the power of the high-pressure flow.

“With the elevation difference, the water coming into our treatment plant is somewhere around 85 psi,” says Matt Trujillo, director of operations. “When we originally installed the raw water pipeline from the Pueblo Reservoir, about five miles of pipe, we had to install energy dissipation through a pressure dissipation building.

“We have three valves that have been in operation since 2003 that break that 85 psi down to 10 to 12 psi so it’s able to go through the treatment process. Now we can use that high pressure to our advantage to create power.”

Old system remains

The pressure relief valves, in a 30-by-30-foot building, get the job done, but they don’t do it quietly. “You drive by and you can just hear the wasted energy, the noise and vibration coming out of there,” Trujillo says. The hydroturbines will be installed in parallel to the existing pressure-dissipation plumbing, so the old valves can still be used if needed.

“A majority of the flow will be directed through the turbines,” says Trujillo. “If we need supplemental flow, or if we have to take down the turbines for maintenance, we can still run through the pressure dissipation building.” Pueblo’s Whitlock Water Treatment Plant, with 84 mgd capacity, has average flows of 22-25 mgd in summer and 10-12 mgd in winter.

Significant savings

The utility purchased 1.0 MW and 0.5 MW hydroturbines. Peak generation is expected to be 835 kW, and annual energy production is projected at 3,500 MWh. “That’s a relatively small fraction of what we use,” Trujillo says. “It’s probably in the 10-20% range.” Nevertheless, it’s a significant savings — an estimated $400,000 a year when coupled with other metering changes.

The plant’s raw water comes in through a 66-inch pipe buried about six feet underground. The turbines will be connected to that pipe underground, and the connecting pipes will come up through the floor of a new building. The pipes will then turn horizontal and run through the turbines. Then the water will be piped back underground to connect with the supply pipe that feeds the treatment plant.

The smaller turbine will be used in winter, when water demand is lower. Although it won’t produce as much electricity, it will run more efficiently. In summer when the flow is higher, the water will flow through the larger turbine.

Pueblo Water serves a large distribution area (580 miles of buried pipelines) at a variety of elevations, so it has multiple pressure zones and storage tanks. “We try to get a healthy pressure for everybody in town, 40 to 100 psi,” Trujillo says. “The only way to do that is to move water to secondary storage tanks.”

That creates a substantial power demand for pumps and motors to move the water through the system; the new hydropower will help meet that demand.

Long time coming

Trujillo always thought generating power from the water supply pressure was inevitable, but it hasn’t been a smooth road: “We’ve been looking at this for 15 years. The biggest hurdle was more on the regulatory side. When we got really serious, we called in a professional.”

Although the Lake Pueblo Reservoir from which the utility draws most of its supply is managed by the federal Bureau of Land Management, the permit for the hydropower project came from the Federal Energy Regulatory Commission.

Pueblo Water has already purchased the turbines, but the project has been delayed because the installation cost exceeded original estimates. “We did the procurement for the turbines ourselves, and next we sent out for bids for the construction,” Trujillo says. “Costs came back quite a bit higher than we expected. Now we are working to minimize the amount we have to contract out.”

He estimates construction will begin late in 2022 and take six to eight months, if there are no material shortages. “On paper it looks simple,” he says, “but it’s a little complicated to have all the equipment in place where we’re taking power generated on site, blending it with power coming from the municipal electric company, and making sure the power we generate doesn’t go back onto their grid, causing them potential issues.”

Once this project is fully operational, the generators will make noise, of course, but not as much as the energy dissipation valves. And when people hear noise as they drive by the treatment plant, it will be the noise of energy produced — not wasted.