Interested in Rehab/Relining?

Get Rehab/Relining articles, news and videos right in your inbox! Sign up now.

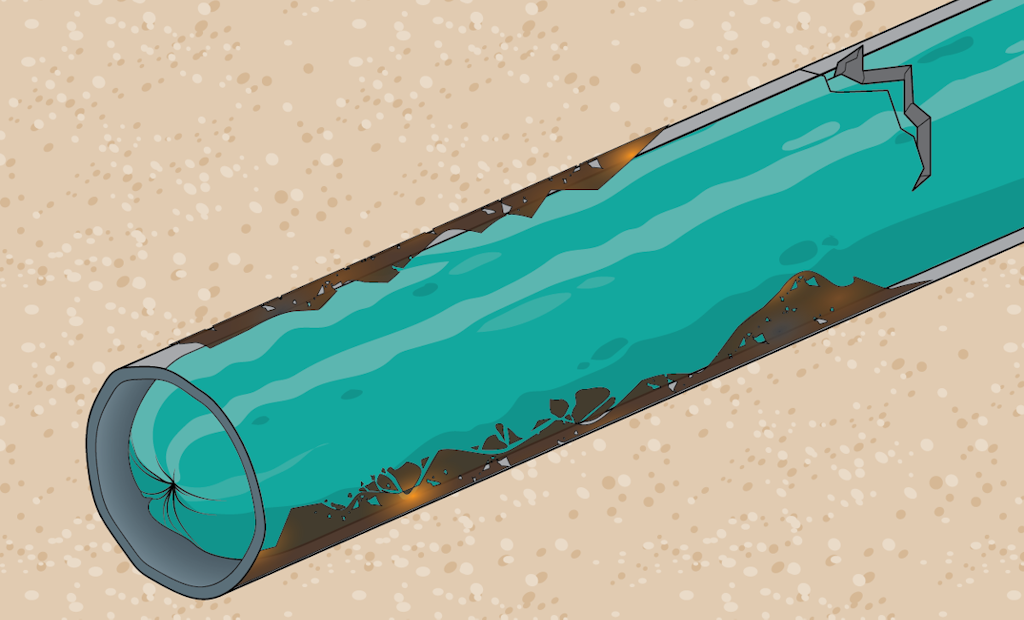

Rehab/Relining + Get AlertsOriginally called “insitu form,” meaning “form in place,” cured-in-place pipe liners were developed in 1971 by Eric Wood in London. Prior to that, trenchless technology methods were limited to sliplining or grouting techniques. But those methods were less feasible: grout is a short-lived solution that is expensive to apply, and sliplining also requires grouting, a measure of trenching and results in significant diameter loss. Wood recognized the opportunity to improve rehabilitation efforts with liners that were cured directly inside the pipe, which led to the invention of CIPP liners. CIPP repairs the damaged pipe with a liner that, essentially, becomes a new, jointless pipe within a pipe. Wood successfully executed the first CIPP repair by pulling a felt liner impregnated with polyester resin through the pipe and finishing it with an ambient cure.

In the United States in the 1970s and 1980s, aging underground infrastructure demanded crucial rehabilitation as well. Because of the success of CIPP in the U.K., the method soon crossed the Atlantic and was adopted by municipalities in the U.S. And the success of CIPP begat further evolution of the technique: operators began experimenting with alternate materials, resins and processes leading to further advancements of the CIPP method.

Throughout the 1980s the search for materials and processes that were more efficient and enhanced performance led to the development of:

- Acrylic felt, glass fiber reinforced plastic and fiberglass-reinforced felt

- Epoxy, vinyl ester and styrene-free resins

- Steam, hot water and UV curing methods

But while working with new materials and processes, it became clear that the combination of materials and methodology were as important as the materials themselves. The fabric chosen plays a role in the strength and durability of the liner and must be compatible with the resin and the curing technology; they are not all interchangeable.

Each combination offers various pros and cons so it's important to choose the right materials for the job. For example, felt can be inverted into the pipeline unlike GFRP, but felt is weaker and bulkier than GFRP; polyester resin is the cheapest but it results in greater shrinkage; and UV curing is the newest method, brought to market in the 2000s, but is almost twice as expensive as other curing methods. These are just a few considerations to keep in mind when determining the best CIPP method to use.

Regardless of the materials and methodology, CIPP is a safe, efficient and cost-effective trenchless technology that quickly became the leading method for pipeline rehabilitation. There have been many innovations to this process since 1970, and CIPP will only continue to evolve as the nation’s underground infrastructure continues to age. One thing is for sure: CIPP is here to stay.

To learn more about CIPP, download the free white paper The Elements of CIPP: Cured-in-Place Materials and Processes.