Innovative pump technologies are continually developed to address the complex needs of the municipal water and wastewater industry, offering advanced solutions for fluid handling and management. From pressure booster systems ensuring enhanced water pressure, rotary lobe pumps catering to the conveyance of viscous and abrasive materials, to cutting-edge grinder pumps designed to reduce non-biodegradable solids, these technologies redefine efficiency and reliability. Take a look at some of the latest pump technologies below.

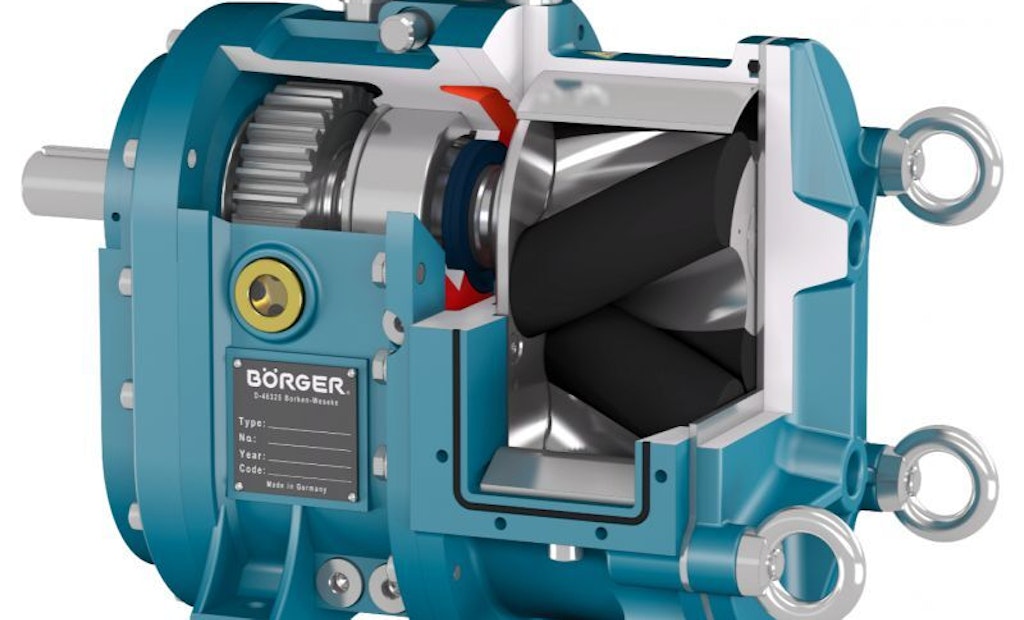

Boerger BLUEline rotary lobe pumps

Boerger BLUEline rotary lobe pumps are a self-priming, valveless, positive displacement pump used for conveying viscous and abrasive materials. They are resistant to wear and provide pulsation-free operation. Operation is fully reversible, with dry run capability and flow rates up to 7,000 gpm. They are constructed with maintenance-in-place design, allowing for all wetted parts to be easily replaced through the front cover without the removal of pipe or drive systems. The pump conveys biosolids (primary, WAS, RAS, digested, thickened, etc.), grease, sewage, scum, lime slurry, alum sludge, permeate and polymers. 612-435-7300; www.boerger.com

A.Y. McDonald E-Series DuraMAC Water Pressure Booster System

A.Y. McDonald’s E-Series DuraMAC Water Pressure Booster System comes complete with easy setup instructions, all metal connections, a half-gallon pressure tank, and check valve. In addition, users experience a quiet operation due to the TEFC single-phase motor. Designed to shut off when no flow is detected, this solution gives an extra boost to water pressure. 800-292-2737; www.aymcdonald.com

Crane Pumps & Systems Barnes RAZOR

The 2 hp Barnes RAZOR grinder pump from Crane Pumps & Systems is suitable for light commercial and residential solids-handling applications. It is designed with axial cutting technology to reduce solids like flushable wipes, diapers and other nonbiodegradable items. Maintenance is convenient with only a single tool needed for disassembly. The plug-and-play cord also provides easy servicing without requiring removal of epoxy in the conduit. Its 1.25-inch discharge is suitable for preconfigured packaged systems and turnkey solutions. It is available in the Barnes EcoTRAN Pressure Sewer System for grinding in tough terrain. It provides a practical and environmentally safe alternative to traditional gravity systems. Numerous configuration options are available. 937-778-8947; www.cranepumps.com

Duperon Dual Auger System

Serving as an alternative to grinders and chopper pumps in the collections system and plant headworks, the Duperon Dual Auger System is comprised of two vertical, electrically driven, counter-rotating augers that catch, dewater, compact and remove rags, wipes and other debris from the waste stream. Each unit has a brushless, 0.71-inch bar screen that passes organics and conveys compacted non-dissolvable debris to a discharge extension chute for disposal, as well as a built-in-bypass to avoid the risk of sewer backups during power outages. Utilities save time and money by eliminating the manual cleaning of clogged pumps. The compact, fully submersible unit can be installed in a wet well or manhole as small as 17 inches. 800-383-8479; www.duperon.com

Industrial Flow Solutions OverWatch

Industrial Flow Solutions’ OverWatch pump system lifts influent at the point of entry, eliminating the wet well. Effluent is contained, eliminating odors and reducing maintenance. The stainless steel body is designed to withstand the effects of corrosion from harsh materials and solutions, making OverWatch an ideal solution for the municipal, industrial and commercial industries. In addition, the system has HMI touch-screen controls to further simplify operations. 860-631-3618; www.flowsolutions.com

JAECO Fluid Systems FRAM pumps

FRAM pumps from JAECO Fluid Systems are hydraulically actuated and designed for accurate, completely leakproof metering of difficult-to-handle liquids. The durable cast iron pumps are available in simplex or duplex with capacities ranging from 0.86 to 56 gph at operating pressures up to 1,200 psi. Liquid end options include 316 stainless steel, PVC or Alloy 20 and include single- or double-ball or poppet spring-loaded check valves. The pumps are customized to each customer’s specific needs and are designed for continuous use with minimal downtime. 877-778-3456; www.jaecofs.com

Pioneer Pump Diesel-Driven Pump Packages

Pioneer Pump, a brand of Franklin Electric, offers a comprehensive range of diesel-driven pump packages including options for fixed and portable installations. These packages are built for tough environments and are available with vacuum-assisted priming, self-priming and standard centrifugal pump ends. Available in sizes up to 18 inches, the centrifugal pumps are designed to provide better flow, higher head and greater efficiency to meet unique challenges. Sound-attenuated enclosures are available for select models. Enclosures are manufactured from heavy-duty sound-deadening material to meet industry standards for noise reduction. All enclosures offer lockable door panels that can be removed in minutes without tools for easy and direct access to the pump. 503-266-4115; www.pioneerpump.com

Romtec Utilities site-specific pumping systems

Romtec Utilities specializes in the engineering and supply of sophisticated site-specific pumping systems for any application. The company supplies wastewater, stormwater, industrial, clean water, and potable pump stations. These packages include complete plan sets, specifications, all station components, documentation, warranty, and on-site services such as startup and testing. Custom designs include wastewater lift stations, stormwater pump stations, industrial process water pump stations, clear water pump stations, booster stations and flood control. 541-833-0761; www.romtecutilities.com

Zoeller Pump 72 HD Series

Zoeller Pump’s 10 and 15 hp 72 HD Series is an expansion to its existing grinder product offering now ranging from 1 to 15 hp. The units include a dual carbon ceramic shaft seal, moisture and thermal sensor, a buna-n gasket to protect the 3,450 rpm motor, and class F windings. Pumps are available in 208, 230, 460 or 575 volts using a three-phase connection. The 3- or 4-inch ANSI flanged horizontal discharge allows for easy adaption to competitor grinder or solids handling rail systems. Pumping performance ranges from 250 feet at shut off and a max flow at 150 gpm at 50 feet TDH. Removable legs clear the bottom of the pump to allow debris to flow easier into the cutter assembly when used with a guide rail assembly. This assembly uses a 440 stainless steel with a Rockwell C hardness of 55-60 cutter and cutter plate in a scissor-like cutting motion that reduces solids down to 1/8 inch. 800-928-7867; www.zoellerengineered.com