Built in 1939, a 9.15-inch cast-iron water main in the Bourne Water District of Cape Cod, Mass., runs above ground as it crosses a railroad bridge, then continues underground again.

The line operates at 95 psi, and no one knew if the old valves worked. A rupture anywhere along the main, but especially over the bridge, would be a disaster for superintendent Ralph Marks. To replace the valves with a conventional shutdown was a planning nightmare. The service area was too large to be temporarily out of water. Exercising the valves, advertising the shutdown, and issuing boil orders added to Marks’ concerns.

Then Ken Ventura, a sales representative for Cape Cod Winwater Works Co. in Hyannis, introduced Marks to the EZ Valve insertion system from Advanced Valve Technologies LLC in Blue Island, Ill. “The technology requires no tapping machine, coupon to cut, or heavy equipment,” says Marks. “It was the perfect solution to our problem.”

Made for ease of use

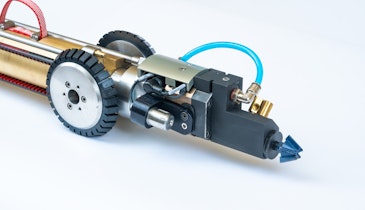

Marks hired Cape Cod Winwater Works to install an 8-inch EZ Valve on either side of the bridge. The installer cleaned and lubricated the pipe surface and rubber gasket of the EZ Valve fitting housing before mounting the valve assembly — a precision-machined ductile iron casting — around the pipe.

After bolting the valve body to the main, he inserted the resilient wedge gate into the valve body, which operates like a standard American Water Works Association valve (C-509-01). “The only difference is that the EZ Valve expands when pressed into the main,” says Ventura. With the valve assembled, the technician installed the power feed drive unit to the valve and pipe, then filled the valve assembly with water for hydrostatic pressure testing. The EZ Valve is rated for up to 250 psi service.

To cut the slot in the pipe, the technician installed a temporary valve, then mounted the EM cutting system and mill cutter to it. The pipe remained under pressure throughout the operation. The EM system cut a slot 120 degrees across the top of the pipe, allowing the resilient wedge gate to be inserted.

Chips ahoy

“This system is much quicker than the traditional method of cutting out a coupon — the top half of the pipe,” says Ventura. “Cutting with the tool takes about five minutes on cast-iron or ductile iron pipe.” An exit hose attached to the valve body removed the cutting chips before they could flow downstream to possibly clog meters and services.

After removing the cutting machine, the technician screwed a threaded completion plug into the valve body through the temporary valve, which he removed. Finally, he positioned the EZ Valve upright and installed thrust-restraint bolts to prevent movement. The resilient wedge automatically aligned to the milled slot, and the valve was operational. Installing both valves took three hours.

“The valves, which provide a bubble-tight shutdown, allow us to control the water main and protect the integrity of the bridge,” says Marks. “They operate exactly like AWWA valves from street level, with the same number of turns and same feel. That’s what really sold me. I will specify EZ Valves for all future under-pressure installations in Bourne.”