When the protective coating on steel water and gas pipelines starts to deteriorate, corrosion isn’t far behind. But trying to locate those corrosion-prone areas with a transmitted current can frustrate technicians, as interference, congestion, and the presence of other metallic structures underground complicate the process.

The latest Pipeline Current Mapper, or PCM+, from Radiodetection Ltd., overcomes that problem with an accurate unit that integrates location and mapping technology, says Peter Mann, pipeline products specialist.

The system is comprised of a transmitter and a handheld receiver. While the transmitter applies a 4 Hz AC test signal to the pipe, the receiver uses advanced digital signal processing to read the signal strength and map the pipeline for up to 29 miles. Current leakage indicates coating defects. The unit’s long-range capability results in fewer transmitter connection points, speeding up surveys.

The receiver, in an all-weather housing, has enough memory to store up to 1,000 data points. It takes three seconds to make measurements, versus eight seconds on the company’s previous model. It also provides real-time, continuous depth measurement, as opposed to only push-button readings.

One pound lighter than its predecessor, the receiver is more ergonomic, runs on dry cell or rechargeable batteries, and has a high-contrast display panel. It is Bluetooth-enabled and so can upload mapping data to a Personal Digital Assistant (PDA) or a PC. Even without a PDA, a technician can download the information from the receiver onto a computer back at the office.

“With the old receiver, you could store readings, download them onto a PC, then manually enter them onto a spread sheet,” Mann notes. “Now, with a software application that’s available on our web site, the receiver can send data to a computer. The data is then automatically displayed in graphical format. You can also plot data live, on the fly, right there in the field, and see right away if there is coating damage.”

If the PDA is equipped with global positioning system (GPS) software, GPS data can be incorporated into the mapping data, allowing production of highly accurate geographic information system (GIS) maps.

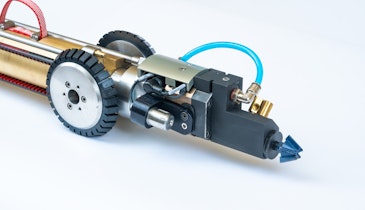

After the receiver identifies a pipeline section with current leakage, an A-frame accessory helps technicians pinpoint the defect to within three feet. This minimizes excavations. Crews then resolve the problem by repairing the damaged coating, applying a rectifier to boost the cathodic protection, or replacing the pipe. For information: 877/247-3797, www.radiodetection.com.