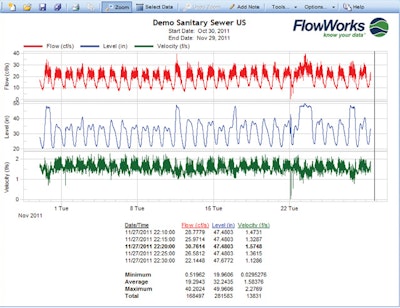

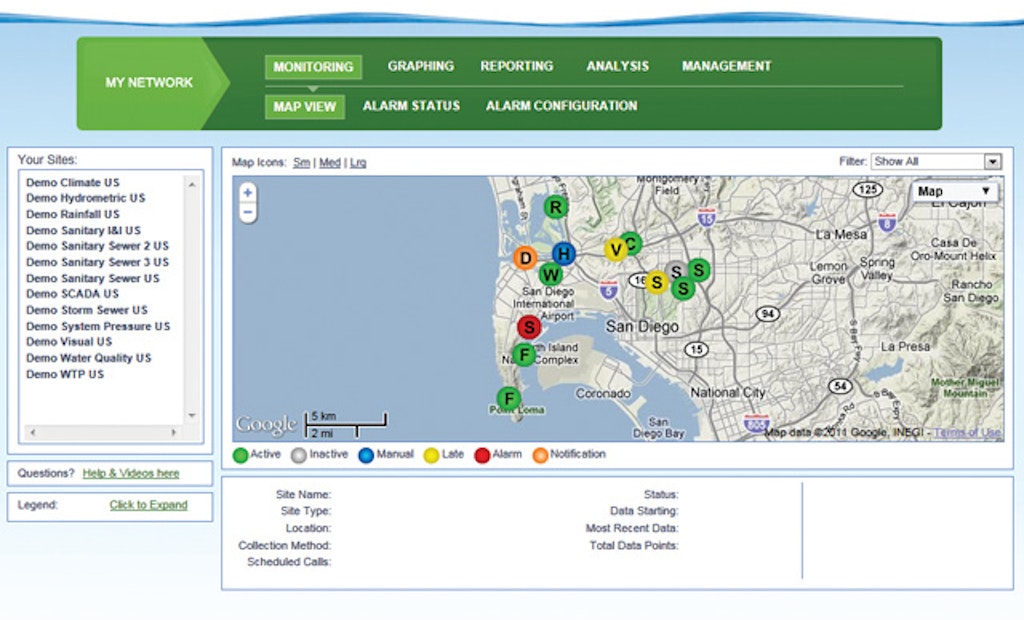

Akey challenge in sanitary sewer flow monitoring has been turning flow information from multiple field devices in scattered locations into readily actionable data. The FlowWorks data management platform from FlowWorks Inc. addresses that challenge.

FlowWorks is a Web-based...