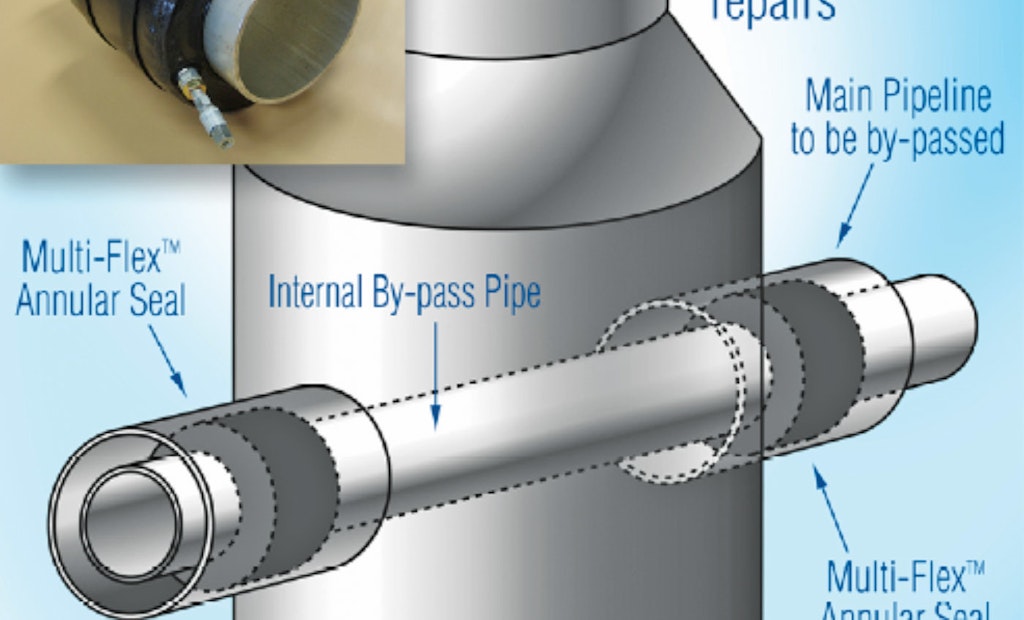

Making a tight seal between two pipes of different diameters can be difficult. That is especially true when those pipes carry fluid that flows at a high speed or may be carrying foreign objects. Multi-Flex Annular Seals from Petersen Products are designed specifically for those...

Seal transitions and simplify bypass applications

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.