Cleaning system eliminates biomass, increases productivity

Problem: Shane Donoghue, a wastewater facilities manager in a large Australian city, saw accumulation of FOG and biomass up to 4 feet deep in a month in a lift station. This required tens of thousands of dollars in maintenance, including weekly to biweekly vacuum truck services and confined-space entry to clean the well by hand. “Sometimes the FOG would build so thick, it was too great of a load for a single truck, and they would have to come back again,” Donoghue says.

Solution: Donoghue purchased the EP-1300 conditioning and cleaning system from Anue Water Technologies to relieve the department’s operations budget. The unit operates by recycling a small amount of discharged flow to create ongoing surface agitation that prevents FOG buildup and promotes aerobic activity.

Result: The installation immediately reduced maintenance checkups from weekly to monthly, and the lift station no longer required continuous vacuuming. “Our need for confined-space entry was just about eliminated,” Donoghue says. When considering the reduction in labor costs, vacuum truck cleaning, and tipping fees, a single unit saved $15,000 in the first year and nearly $22,000 in the second year. The change in cleaning routines reduced maintenance costs by nearly 50 percent. 760-727-2683; www.anuewater.com.

Packaged pump system used in switch to sodium hypochlorite

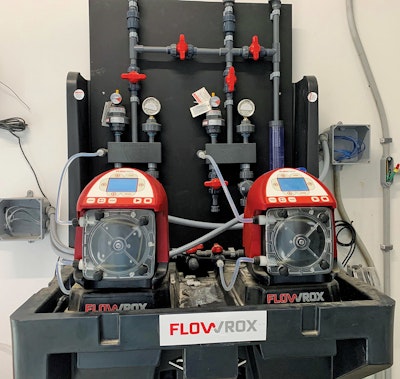

Problem: The city of Camden, Tennessee, was in the midst of a project to change its disinfection system from chlorine gas to sodium hypochlorite. The city needed a metering pump system that could fit in a limited space.

Solution: The city selected two Flowrox Packaged Pump Systems that incorporated two pumps each. Flowrox pumps were ideal because the peristaltic pumps don’t vacuum degas on warm summer days. Also, the pumps are ideal for suction lift duties. The systems were equipped with manifold blocks, safety relief valves, gauges, and shut-off valves and have an integral tube leak detector. The base the pumps sit on also performs as spill containment for mishaps and can be equipped with safety drains and even alarms.

Result: The plug-and-play systems have performed as advertised. 888-356-9797; www.flowrox.com.

Control valve key to sludge removal at hydroelectric plant

Problem: The Guadalupe Hydroelectric plant operates three turbines that require cooling. The cooling system collects water from a holding tank that has screens to filter fine sand particles. The sand is decanted in the bottom of the tank and can get up to 8 inches high in a period of six months. This gradually decreases the efficiency of the cooling system, resulting in an average 26-hour suspension of plant operations to deploy 10 people to drain, remove sludge and refill the tank.

Solution: A sludge removal system was designed using a network of high-pressure sprinklers on the bottom of the tank to stir the sludge and then discharge the muddy water through a submersible pump. In order for this design to work, it was imperative that the pressurized water to the sprinklers was regulated to flow at a constant 2,377.50 gpm. A Singer Valve 10-inch 206-2SC-MV - Class 300 control valve was chosen because it combines precise flow control with flowmetering to ensure that the flow is adjusted to supply water at stable pressure.

Result: The sludge removal has changed from a manual cleaning to an automatic six-hour process, and it has decreased generator maintenance as the water quality in the cooling system has significantly improved. “By regulating the flow with Singer’s control valve in our new sludge extraction system, we have reduced our maintenance costs and reduced interruption of power generation,” says Carlos Ospina, operations director for the plant. 888-764-7858; www.singervalve.com.

Rural collections system simplifies lift station maintenance with above-ground systems

Problem: The city of Perryville, Missouri, employs a small staff to manage its lift station network, which is spread over many miles due to its rural nature. Typical submersible-type lift stations are burdensome due to their unreliable performance, time-consuming confined-space entry and frequent pump replacements. The result was high labor and parts costs and frequent downtimes. “With submersible pumps, when you pull those, you tend to end up breaking other components in the lift station and having more down time,” says Linda Chappius, maintenance technician.

Solution: Today, the city operates six above-ground Wet Well Mounted Pump Stations from Smith & Loveless. These systems feature all pumps, valves and controls housed above ground-level and outside of the confined-space wet well. “You don’t have to be in the wastewater and dealing with all the hazardous situations,” Chappius says.

Result: Chappius safely and conveniently inspects each of the stations daily without the extra requirements associated with confined-space entry. This has helped the city achieve continuity of maintenance and simplify its regular maintenance program for pump stations. As a result, the city has received superior longevity from the systems. The first station the city installed in 1995 is still in operation today, more than two decades later. “It’s been a tremendously good lift station,” Chappius says. “For where it’s located and what it goes through for day-to-day use, it’s an excellent piece of equipment.” 800-898-9122; www.smithandloveless.com.

Pump helps municipality prepare for imminent hurricane season

Problem: Until recently, a Florida municipality frequently encountered significant increases in wastewater flow at their treatment plant due to surface and groundwater entering the collections system during major rain events. The plant could not safely discharge the disinfected wastewater fast enough, resulting in the discharge of over 200 million gallons of untreated wastewater into a major public waterway.

Solution: The general contractor quickly implemented the first phase of the municipality’s action plan by drilling an 800-foot injection well. It was designed to accept the maximum permitted flow of 22 mgd of treated wastewater. The well was estimated to have a hydrostatic pressure of 105 psi. The massive flow rate at such high pressure presented a unique challenge. The general contractor and the municipality asked Thompson Pump to design, manufacture, and deliver four 12-inch, high-pressure, diesel-driven pumps. In addition to the high flows and pressures required, each required 315 hp, sound attenuation to 74 dBA at 23 feet, and Final Tier 4 emission-compliant diesel engines.

Result: After the pumps arrived on site, high-pressure discharge piping was constructed and suction piping installed. The pumps were ready for testing several weeks after delivery. Each achieved full prime in less than 45 seconds, due to the company’s oil-less vacuum technology. With all pumps operating at 1,600 rpm, they were able to achieve a flow rate of 15,277 gpm. During Hurricane Irma, the plant effectively treated and stored all wastewater coming into the plant, with no reports of wastewater spill. 800-767-7310; www.thompsonpump.com.

Submersible chopper pump stands strong through tropical storm

Problem: The main lift station serving the wastewater treatment plant in Morgan’s Point, Texas, continually experienced problems with its three standard nonclog pumps. The pumps frequently clogged when rainfall totals reached or exceeded 2 inches — with shop rags, pieces of lumber, plastic bottles, gloves, and wet wipes all commonly clogging the pumps when the standard demand increased. Over a 7-year period, these issues required the city to spend around $100,000 to maintain and service the three pumps.

Solution: The city approved a Vaughan SE-Series Submersible Chopper Pump, along with a complete guide rail system to solve the frequent clogging problem.

Result: Since the Vaughan pumps were installed in late July 2016, the city has experienced over 100 inches of rainfall with no plugging incidents or other issues. During Hurricane Harvey in 2017, the pumps ran continuously for 72 hours with no plugging incidents and no problems while pumping over 2.5 million gallons of unscreened sewage through the lift station. “I just wish we had purchased these pumps years ago to eliminate the maintenance headaches we endured and the costs we incurred keeping our previous pumps in operation,” says Brian Schneider, city administrator for Morgan’s Point. “If the former pumps were still installed, all of the residents would have had sewage in their homes.” 888-249-2467; www.chopperpumps.com.