Inflow and infiltration in the wastewater collections system draws a utility’s attention. It’s an ongoing threat for sanitary sewer overflows and has a substantial cost once it is received at the wastewater plant. As one senior plant operator puts it, “I don’t like paying...

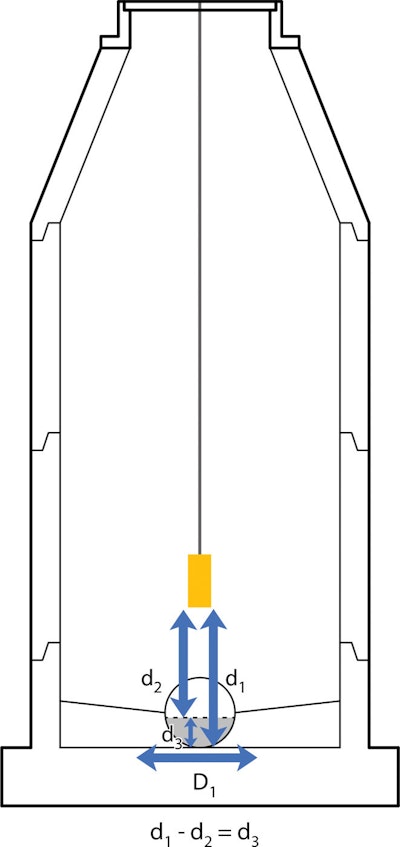

The Lure of Level-Only Meters

There are many variables at play when measuring I&I, and a lone measurement doesn’t always tell the tale.

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.