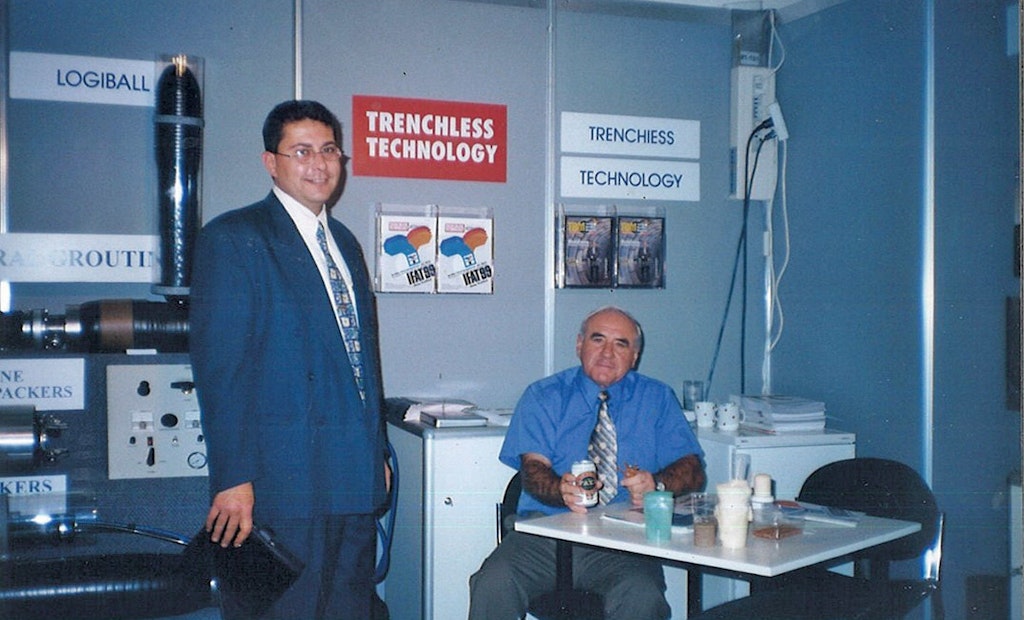

Current Logiball President Marc Anctil and company founder Roger Bissonnette exhibiting at a European trade show in 1999.

Some people search for solutions. Some people create them.

Count Roger Bissonnette firmly among the latter. Bissonnette, a civil engineer and trenchless rehabilitation contractor, was searching for equipment that suited his needs back in the early 1980s. He attended trade...