At first glance, Green Bay, Wisconsin, and the East Bay area of northern California don’t share a ton in common. From weather to population size, they’re very different places. Yet with their locations on Lake Michigan and the Pacific Ocean, both communities are defined in many ways by their connection to the water.

The East Bay Municipal Utility District and Green Bay Water, both profiled in this issue of Municipal Sewer & Water, provide clean water to their residents. Their approach to that mission highlights their similarities and the value of a proactive operational mindset.

In the East Bay area, where earthquakes can pose significant problems for underground infrastructure, maintaining a resilient transmission system brings extra challenges. And for residents of Alameda, an island city in San Francisco Bay, the reliability of that system takes on added significance.

Alameda is served by four pipelines carrying water under the harbor from Oakland. The pipelines are the island’s only source of water, and three of the lines are made of aging cast iron that’s more susceptible to potential earthquake damage. On top of that, the city has no reservoirs or storage tanks to hold emergency water supplies, so the utility is working toward replacing these critical pipelines with new earthquake-resistant lines.

The first of these new lines is Alameda’s primary water feeder, a 3,300-foot-long run of high-density polyethylene pipe carrying approximately 25 million gallons of water per day.

The line, which runs 155 feet below the harbor floor, was completed in January at a cost of $26 million after about a decade of planning and also included the open-trench installation of 11,000 feet of pipe to connect the new pipeline to the existing transmission system.

Back in Green Bay, the projects look different but the approach is much the same.

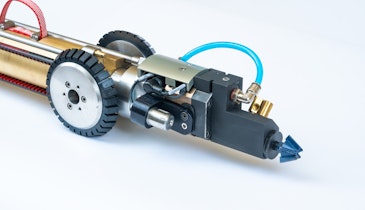

Last summer the utility took on the cured-in-place rehabilitation of 1,400 feet of 8-inch cast iron water line. The line had a history of leaks that caused ground disturbance. At the same time, the street above was in good condition and the line was still adequately sized, so the utility decided the time was right to take on its first water-main lining project.

And when the 36-inch main transmission line running 25 miles from the utility’s filtering plant needed a full assessment, they brought in new technology to get a clearer picture of what was happening. The result of that effort, and subsequent inspection work, has allowed the utility to make the line more resilient without unnecessary rehab or replacement of pipe that was in good shape.

It’s all part of Green Bay’s approach to proactively seeking out new technologies and processes that make their operations more efficient and effective.

Both of these utilities demonstrate the value of this approach. Gaining efficiency and effectiveness should be part of the operational mindset for every utility. I hope it’s part of yours.

Enjoy this month’s issue.