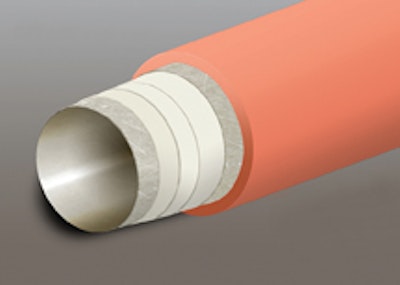

Pipe bursting and cured-in-place pipe lining are proven methods for rehabilitating aging and deteriorated pipes. Being cognizant of available pipe bursting, lining and piercing technologies can help you choose the most effective sewer rehabilitation tools.

Crew members...