Interested in Infrastructure?

Get Infrastructure articles, news and videos right in your inbox! Sign up now.

Infrastructure + Get AlertsA cross bore occurs when one underground utility line intersects another. Cross bores are particularly dangerous when a gas line intersects a sewer line. This happens during horizontal directional drilling, a technique for installing a gas line using a remotely piloted drill head. During HDD, installers must rely on city asset maps to avoid existing sewer pipes. Erroneous or incomplete map data can create the potential for a cross bore. When a cross bore occurs, the intersecting gas line can snag debris in sewer effluent, causing a clog. If that clog is forcibly cleared, the gas line may rupture and leak into adjoining buildings, where it presents serious potential for explosion.

For reasons of public safety and liability, utilities are vigilant about inspecting sewers for cross bores whenever and wherever they install a gas line. Moreover, most cities require cross-bore inspections, and often hire outside contractors to perform them. Because the risks are so high and several stakeholders must coordinate their efforts and share their findings, any successful cross-bore location program requires a robust inspection data management platform.

Top software solutions offer benefits tailored to the task of cross-bore location. For instance, WinCan Web stores inspection data in the cloud, giving all stakeholders (cities, contractors and utilities) secure, easy access to it. Having inspection data available universally accelerates inspection and analysis and narrows the window of risk. Inspections can be uploaded wirelessly on the go, allowing utility and city engineers to immediately confirm the absence of a cross bore. Cloud data also prevents versioning error, because users have access to up-to-the-moment information.

WinCan also brings a high level of standardization to data collection and supports lateral-specific observation catalogs like NASSCO’s LACP. With standardized data, you can compare inspections of different assets performed by different operators with assurance that subjectivity and human error have been minimized, and confidence that comparative condition can be used as a sound basis for prioritizing maintenance and repair. WinCan also makes it easy to aggregate inspection data into rich, customizable reports.

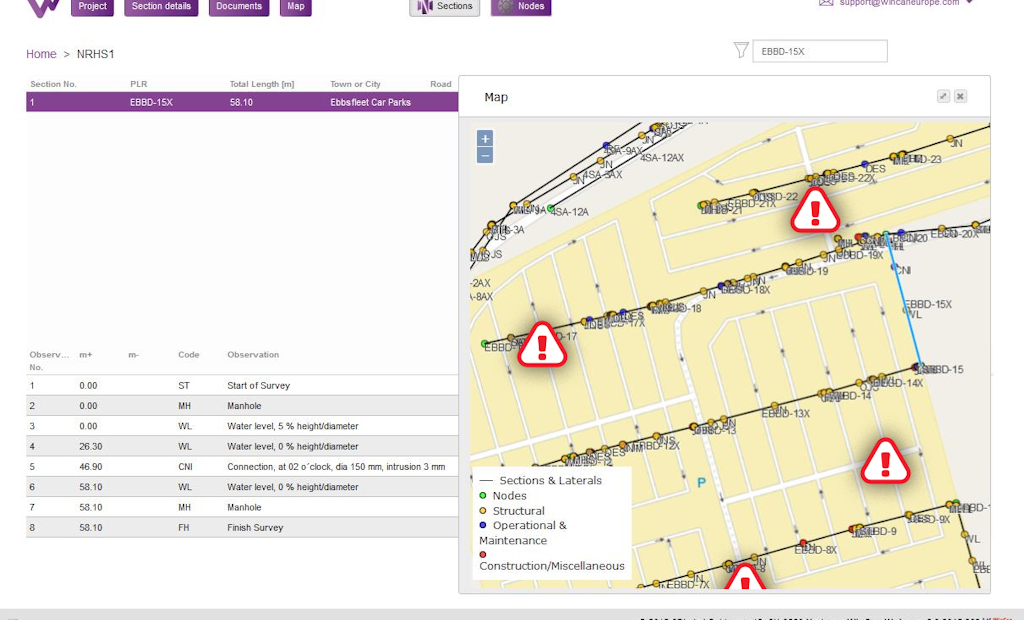

WinCan Web supports web-based maps. Mapping cross-bore data in real time saves resources and time, and aids in visualization and analysis. WinCan Web’s seamless integration with GIS mapping systems allows access to both inspection data and asset maps. Utilities can analyze problem areas and assess their drilling processes, improving their ability to prevent cross bores in the future.

Ultimately, having a robust cross-bore detection program relies on the right lateral launch inspection equipment and the best software to collect, analyze and share the data it generates.

Learn how WinCan Web can improve your cross bore inspection workflow by requesting a demo: Request Demo