Interested in Trucks?

Get Trucks articles, news and videos right in your inbox! Sign up now.

Trucks + Get AlertsStruck-by, struck-against and back-over incidents are far too common:

- 421 Hudson St., Manhattan, New York City, April 21, 2016: Construction worker killed by scaffolding plank.

- Woods Hole Golf Club, Falmouth, Massachusetts, April 21, 2016: Construction worker injured in back-over accident.

- Interstate 440-East, Raleigh, North Carolina, April 19, 2016: DOT workers seriously injured when motorist crashed into highway maintenance truck.

They can happen any place at any time, which is why they’re so difficult to prevent. Contributing factors to struck-by incidents include:

- Poor visibility when working at night or in inclement weather;

- Untrained workers using tools improperly, wearing the wrong (or no) PPE, or engaging in horseplay;

- Fatigue distracting workers or motorists in a dangerous work zone.

Many believe that these incidents are actually "accidents" resulting from a series of unfortunate events. OSHA doesn’t see it that way. According to OSHA, labeling struck-by events as accidents suggests a lack of control. Because you don’t have the luxury of disagreeing with OSHA on semantics, approaching struck-by events as preventable incidents will result in more positive outcomes for your business.

With that in mind, preventing struck-by, struck-against and back-over incidents comes down to optimizing situational awareness and committing to a safety culture.

Struck-by awareness: Plan for the worst-case scenario

How do you increase awareness for all of your employees? Plan for the worst-case scenario. Another way to look at it is, “Expose all your blind spots.” Examples include:

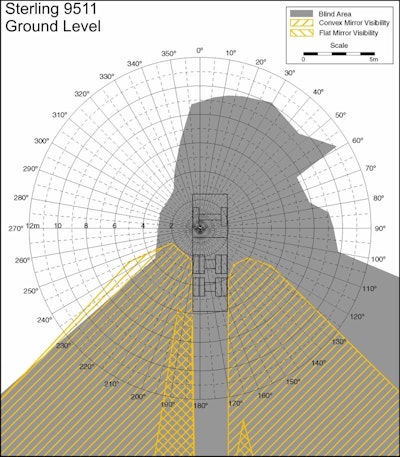

- Install backup cameras in all heavy equipment;

- Implement internal traffic control plans (ITCPs) to coordinate vehicles flow, equipment and workers in a work zone;

- Be vigilant about PPE and training: Enforce those zero-tolerance policies;

- Protect hearing and ensure clear communication among all workers;

- Install proximity sensors on rolling equipment to warn workers that get too close.

This is by no means a complete list. You’ll want to customize the measures you need to optimize situational awareness on your job site or in your work zone.

The goal is to get clear visibility into all of your blind spots. Can’t afford to retrofit all of your older equipment with backup cameras? Then make sure you compensate with specific communications strategies, traffic plans, alarms and training.

Commit to safety culture

The only way to gain traction with your proactive safety plan is to go all-in on safety culture. Only when safety is as automatic as “measure twice, cut once” will you have total buy-in from all workers.

Take the scaffolding incident mentioned at the beginning of this article. Would it surprise you to learn that a “stop-work order” was issued before the accident, specifically for the scaffolding? That’s a safety culture failure.

That incident investigation is ongoing, so it’s not fair to speculate on the specific cause. It is fair to assume, however, that if a journalist can uncover the scaffolding violation then that contractor is exposed, from a risk standpoint.

Without a safety culture, you’re endangering your business as well as your workers.

Being known for your safety culture does more than just limit exposure. There are financial ramifications, too. Struck-by incidents caused 8.4 percent of all construction fatalities in 2014, according to OSHA. Struck-by and struck-against injuries in all industries amounted to $7.16 billion in workers compensation costs, according to the 2016 Liberty Mutual Workplace Safety Index.

The flip side of the cost coin is revenue. According to a recent Dodge Data & Analytics SmartMarket study, “Contractors who prioritized safety also saw greater project ROI (75 percent), and better employee retention rates (79 percent) and were able to attract the most employees (67 percent).” Contractors rated as less safety conscious reported only 38 percent ROI.

Laws of Murphy and Yhprum

The pessimist follows Murphy’s law: Anything that can go wrong will go wrong. From a struck-by safety perspective, having a healthy respect for Murphy’s law can motivate you to plan for the worst. But it doesn’t mean you have to be a pessimist.

It does mean that you have to be proactive about and accountable to struck-by dangers through an ingrained safety culture. Then you can work according to Yhprum’s law: Anything that can go right will go right.