Advancements in technology allow manufacturers to improve safety and ease of operation. The G2X is GapVax’s next-generation addi- tion to its MC series of combination jet/vac units, and it was designed with end users — and their safety — in mind.

The G2X unit is designed with quick and easy engagement of all components, easy-to-read display screens at the front control box (optional screen inside the cab). Push-button operation with on-screen guidance, smooth operation with joystick and wireless controls, and dump/washout functions from the wireless remote are all features for safer operations.

The unit also includes fuel consumption tracker; water consumption tracker; accumulated footage counter with 10 stored distance counts; and a job card that tracks date and time, current, accumulated and total footage, total gallons used, average jetter pressure, peak pressure, fuel used, and fuel rate.

A USB port allows for easy download of data to Excel format, along with complete system and chassis diagnostics.

MC Series chassis

The GapVax MC Series is built on a chassis with an extended front frame rail. This extension provides rigid support for the front hose reel, maximizing stability. “Our units are built to increase the truck’s capabilities and last a long time,” says a GapVax spokesperson. “Our units are designed by the operator, for the operator.”

The GapVax MC Series unit is made of 3/16-inch ASTM A572 Grade 50 Exten steel. The debris body ranges from 5 to 12 cubic yards (stainless steel available). The stainless steel water tank has a 2,000-gallon capacity, while the unitized water and debris tank features a double subframe.

A heavy-duty double acting single-lift cylinder provides a stable 50-degree dump angle. The MC Series vacuum pump options range from 3,500 to 5,000 cfm with up to 27 inches Hg and is a wet-only vacuum truck.

Features and service

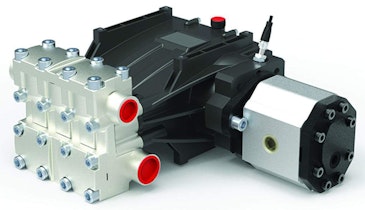

The MC series is also equipped with an 8-foot, front-mounted, telescopic boom with dual lift cylinders reaching 26 feet with a 180-degree rotation. The front-mounted hose reel has an 800-foot by 1-inch hose capacity. The standard water pump is rated at 80 gpm at 2,000 psi, and other water pumps are also available.

Other options include a washdown system; hydroexcavation package; extra storage space; heated boxes; liquid level load indicators; remote pendants and wireless remotes; additional work lights; tube racks; and a remote diagnostics system that allows for less wiring and hoses.

“We believe customer service is a necessity for maintaining successful relationships with our customers,” says the spokesperson. “Our dedicated team of service technicians is only a phone call away and will come to you when needed. Our service team is on call 365 days a year, 24 hours a day. We have a full selection of parts and accessories, not just for your GapVax unit but other brands as well. Our Gulf Coast office also has parts on hand.”

GapVax is a manufacturer of industrial and municipal vacuum trucks. The company offers a full line of accessories, hoses and replacement parts. GapVax has five regional sales managers and 15 dealers to meet the needs of its customers. Founded in 1989, GapVax specializes in custom-built equipment that is easy to operate and maintain. Superior performance and high-quality components are priorities for the company, which is located in Johnstown, Pennsylvania, with a secondary location in Deer Park, Texas, and a nationwide dealer network. 888-442-7829 | www.gapvax.com