Interested in Infrastructure?

Get Infrastructure articles, news and videos right in your inbox! Sign up now.

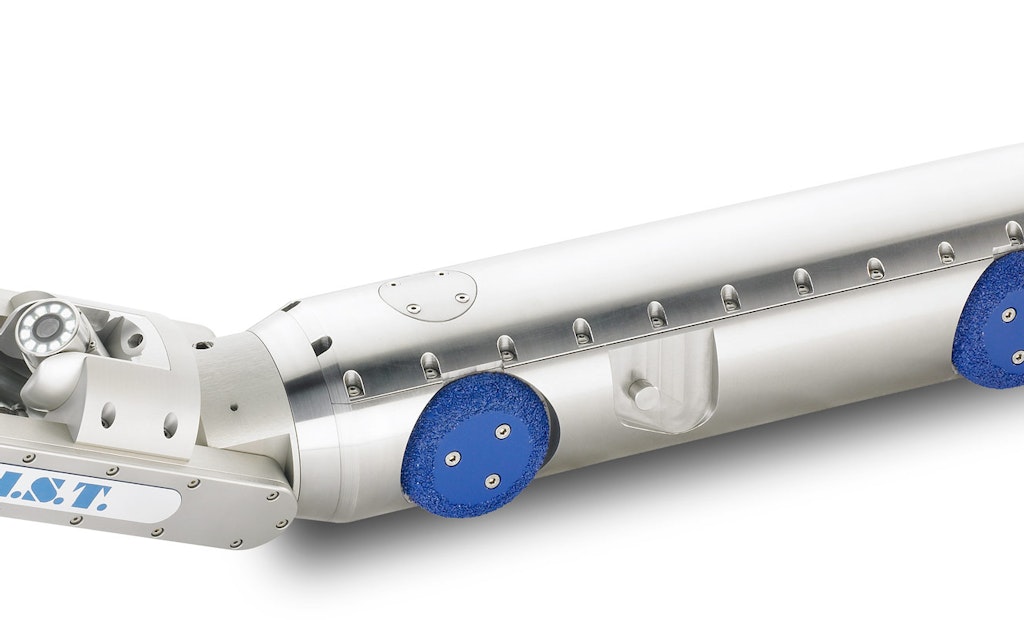

Infrastructure + Get AlertsDelivering up to 1.9 hp cutting power, the new air-powered IST PC200 from Pipeline Renewal Technologies makes quick work of lateral reinstatement. For optimum range and precision, its cutting arm articulates on four axes, each proportionally controlled with encoder feedback to reach and remember any cutting position in 8- to 28-inch relined pipe. The system is built on CANbus control architecture, which not only allows concurrent motion on all axes, but enables remote diagnostics, onboard temperature/pressure/humidity/pitch/roll sensing, easy accessorization, and swivel/zoom of the onboard camera.

“The IST PC200 makes remote cutting feel a lot less remote,” says Pete Kurz, business manager at Pipeline Renewal Technologies. “With four encoded cutting axes, you can reach practically anywhere and always stay oriented. And with a camera that swivels 200 degrees and zooms 10X, you’re never working blind. Yet despite this precision and agility, the PC200 is simply one of the most powerful cutters in its class.”

In addition to its high-powered air motor, the IST PC200 lifts and rotates the cutting arm hydraulically for extra-strong feeds and plunge cuts. High-torque wheel drive motors propel the cutter as far as 300 feet into pipes, and a remote-operated brake holds the system firmly in place for steady cutting. To maximize reliability, supply lines run through the crawler but separate from the electronics, and a rear-viewing camera helps prevent entanglement during extraction. Likewise, a Kevlar member within the control cable is crimped back over itself within the terminal connector to provide exceptional break strength.

Twin multi-function proportional joysticks make it easy to control all axes of motion, and a ‘home’ button restores all axes to their default positions. Additional controls address braking, cruise control and camera illumination, swivel, focus, zoom and rinse. A digital display shows all environmental parameters, plus the bend angle at each axis.

“The crawler knows how it’s oriented in the pipe, and exactly how the arm is articulated,” says Sean Lemcke, product specialist with PRT. “This makes it easy to pinpoint a lateral during pre-inspection, and then navigate directly to it after relining for guess-free reinstatement. This is even more important with UV lining, where the absence of a dimple makes it almost impossible to eyeball a lateral’s location.”

Vehicle-mount and portable versions are available. The control cable comes on a fully automatic motor-driven reel in lengths of 460 and 722 feet. The air/water supply hose comes on a manually wound reel in lengths of 197 and 328 feet.

The IST PC200 is available for immediate demonstration and order.

About Pipeline Renewal Technologies

Pipeline Renewal Technologies is an Envirosight company focused exclusively on the pipeline rehabilitation market. The company offers technologies for no-dig structural lateral connection, lateral and lateral reinstatement cutting, durable point repair, and infrastructure measurement. Pipeline Renewal Technologies is a member of NASTT and NASSCO.