Interested in Inspection?

Get Inspection articles, news and videos right in your inbox! Sign up now.

Inspection + Get AlertsLike many industries, sewer inspection benefits from technologies developed elsewhere — typically for consumer goods (microcameras, digital video, digital control networks), or for larger industrial sectors (XYZ probes, profiling, laser distance measurement). There's certainly been no shortage of technological innovation in the past two decades.

Ultimately, manufacturers must place bets on which specific technologies offer true benefits to sewer inspection professionals and develop products that leverage them. Generally, they succeed when the technology offers new efficiency (demanding less time, lower cost or fewer resources), improved safety or enhanced data. Side-scanning technology is unique in that it offers a multitude of efficiency gains and a better quality deliverable — and that's one reason why so many manufacturers have recognized it as part of sewer inspection's future.

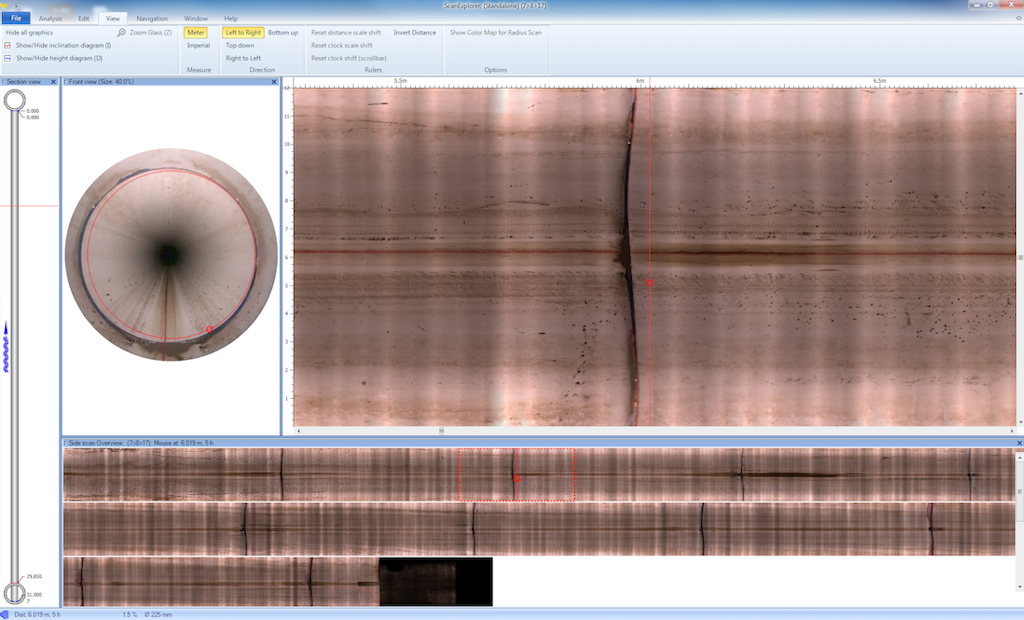

Side-scanning technology enables rapid assessment of pipelines while providing the data needed to prioritize rehabilitation and maintenance. Side-scanning relies on software to manipulate video frames into a flat digital image. The length of the image corresponds to the length of the pipe and the height corresponds to the circumference, as if you pulled the pipe out of the ground, cut straight down its length and were able to lay the whole thing flat.

CCTV footage is vital for maintaining sewers but is time-consuming to collect and analyze. Side-scanning lets your operator focus on doing what they do best, piloting the crawler. No need to analyze on the go or pause and zoom in. A side-scanning system can scan 50 feet of pipe per minute, allowing you to get more done.

Side-scanning makes analysis go faster too. Without having to watch hours of video footage, your engineers can drill right down to the important spots, mark them up on the screen, measure flaws and correlate all that data with additional information captured along with the side-scan (like temperature and inclination). Side-scanning gives municipalities a deliverable that is easy to share, archive and revisit whenever needed.

Interested in learning more about side-scanning technology? Download the whitepaper: “Side-Scan Sewer Inspection Comes of Age."