WinCan is always looking ahead at ways to integrate new technology into its software, including the use of artificial intelligence for automatic defect recognition and classification.

The company’s new AI toolkit, Sewermatics, helps improve operator accuracy, automatically detects defects in video inspections, assigns defect codes and auto-populates data like size, position and water level in 30 languages.

MORE DATA IN LESS TIME

AI in the world of sewer management aims to achieve two main goals: increase productivity and provide more accurate insight into the condition of wastewater infrastructure. AI technology can inspect and classify defects much faster than the human eye or traditional software, improving operator efficiency. And the more information AI can gather, the more data and insight can be gained from inspections.

“Our primary goal with Sewermatics is to assist sewer professionals in the field and in the office,” says Mike Russin, WinCan’s general manager for North America. “For an unassisted inspection, accuracy can range from 50% to 100% depending on city requirements, contractor quality and the inspection equipment used. Sewermatics, with its own accuracy of approximately 85%, has the potential to dramatically raise the lower end of this range, helping these sewer professionals deliver results more efficiently and with greater precision.”

Sewermatics will be available across the company’s full lineup of sewer inspection reporting and wastewater asset management solutions, including WinCan VX, WinCan Embedded and WinCan Web.

MODE OPTIONS

Sewermatics is available in three different modes: Assist Mode, Scan Mode and Web Mode.

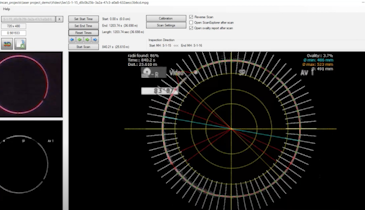

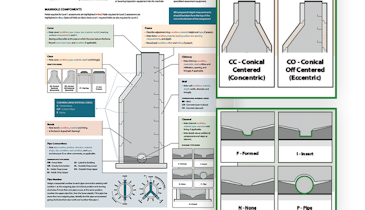

Assist Mode can be used in the field during live inspections, or in the office while reviewing footage. In this mode, potential defects are highlighted and a defect or feature code is recommended according to the standard chosen, whether PACP, WRc, ISYBAU or another. Once confirmed by a human, an observation is automatically created and various parameters like clock position, crack length and water level are prefilled.

In Scan Mode, the software processes inspection footage at an expedited speed, detecting defects and generating observation records as needed.

Similarly, in Web Mode, inspection video is processed and observation records are generated, but the data and reports are automatically uploaded and stored in the cloud, in WinCan Web.

BATCH VIDEO PROCESSING

Sewermatics can also process collections of archival video and create individual reports for each section of the pipe. For the entire collection of videos, the software conducts a system-wide analysis that pinpoints critical risks and organizes them in a list by priority, including cross bores, collapses, holes and offsets. That list can then be used by departments to develop a comprehensive maintenance plan to mitigate damage and deterioration.

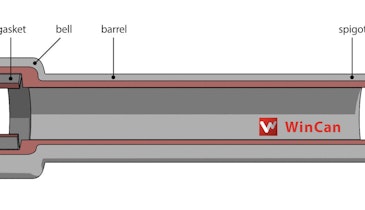

WinCan was the original pipe inspection and asset management software when it entered the market in 1990. Today, it’s a trusted pipeline software brand worldwide thanks to continuous innovation and exceptional support. WinCan transforms raw inspection data into the intelligence municipalities and contractors need to make critical maintenance decisions. The software’s measurement tools help quantify defects, and sophisticated search capabilities filter observations by any combination of criteria. Its report generator automatically summarizes inspection findings using a standard or user-defined template. Native support for GIS mapping, side scanning and AI are among WinCan’s most innovative features.

877-626-8386 | www.wincan.com