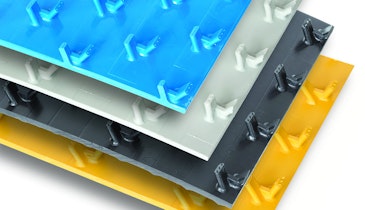

Durability, corrosion resistance and toughness are paramount in the CIPP industry, which is why the newest resin in Perma-Liner’s catalog, Vinyl Ester, focuses on those very same qualities. The product is a result of industrial market demand and was launched by Perma-Liner in July.

When it comes to certain specific applications where fluid temperature is relatively higher, resin has an advantage over epoxy. The demanding needs of many applications including high-pressure or corrosive environments are also met with the Perma-Liner Vinyl Ester.

Its molecular architecture delivers a number of benefits, including superior mechanical properties and excellent catalyzed pot life. The Vinyl Ester also meets the requirements of the California Greenbook pickle- jar test. Another key benefit is its low cost.

Perma-Liner’s Hybrid Vinyl Ester resin is an eco-friendly option with a high-rigid polymer backbone. Some key features to this resin include snap cure, good catalyzed stability, high- temperature performance, and resistance to sag and draining around vertical surfaces and reinforcement. It has no styrene and no volatile organic compounds.

Perma-Liner’s proprietary two-part silicate resin system is highly chemical and heat resistant and self-extinguishing. This resin can be used in critical areas such as the chemical industry, airports, tunnels, municipal utilities, sewer laterals and more.

While this silicate resin can be used in a wide range of ambient temperatures with predictable and consistent cure times, it also has negligible shrinkage and superior bonding.

All three resins listed above cure in under three hours and have a pot life of 25 minutes, or can be adjusted as per project requirements. With their quick cure time, it’s possible for crews to complete multiple repairs in a single day.

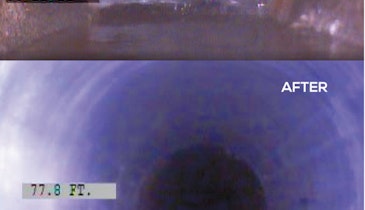

Perma-Liner materials have been tested to an installed 50-year life and come with a 10-year manufacturer’s warranty. With Perma-Liner’s trenchless rehabilitation equipment and materials, the benefits to a community or homeowner — as well as to contractors and government officials — are greater than a typical dig and replace, according to a company spokesperson.

Evolution of trenchless technology

For nearly 20 years, Perma-Liner Industries has developed and evolved trenchless technology and materials to benefit municipalities and contractors. The company has a large distribution network of certified installers nationwide and is a leader in the 2- to 54-inch CIPP industry.

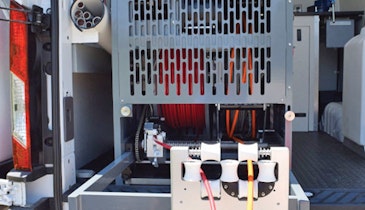

“Our experience in the CIPP industry has allowed us to design, patent and manufacture state-of-the-art technology,” says the company spokesperson. “Based on the design of the equipment and materials, Perma-Liner has the ability to offer compact, user-friendly systems while providing hands-on training and 24/7 support throughout the business partnership.”

The company’s products range from liner material and spot-repair system to heat-assist equipment and lining systems, according to the spokesperson. “Another material we offer is our aforementioned resin, particularly our environmentally friendly Vinyl Hybrid Snap Cure system, high-performance Vinyl Ester and styrene-free silicate.”

Perma-Liner Liner is a leading manufacturer and supplier of trenchless pipeline rehabilitation equipment and materials in North America. Since 1999, the company has developed systems to rehabilitate existing sewer systems without excavation. 1-866-336-2568 | www.perma-liner.com