Interested in Flow Control?

Get Flow Control articles, news and videos right in your inbox! Sign up now.

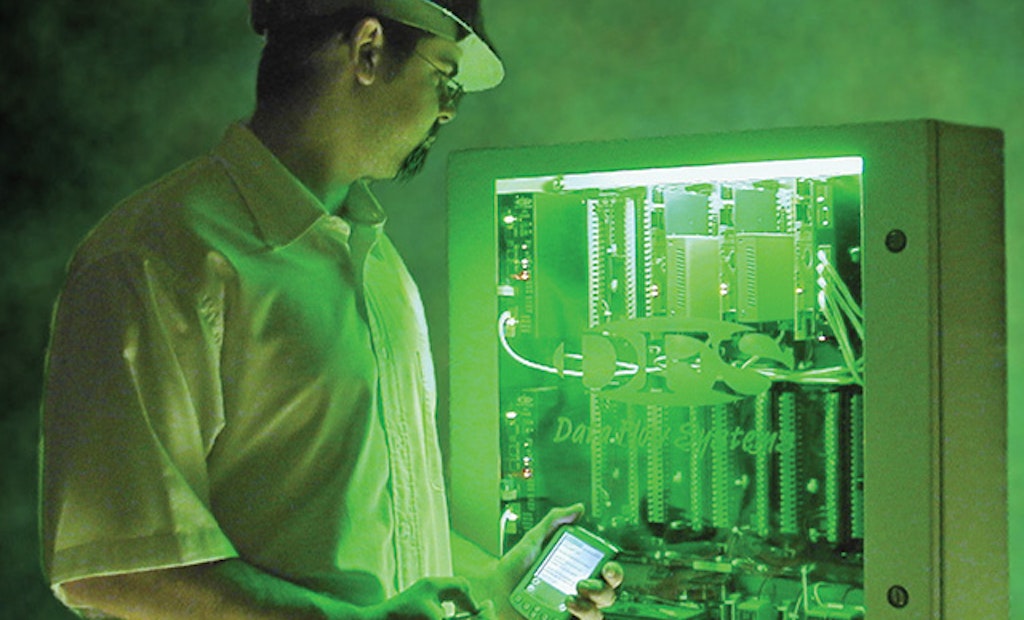

Flow Control + Get AlertsSCADA system

The TAC II SCADA system from Data Flow Systems provides remote monitoring, control and automation solutions for wastewater and freshwater utilities. The system features user-friendly HMI software, no-cost SCADA software licenses, a plug-and-play design, ease of integration and durability in harsh environmental conditions. The unit provides a true obsolescence-proof solution and is made in the U.S. 321/259-5009; www.dataflowsys.com

Pump station control

The PSL 5.0 pump station level controller from Greyline Instruments features redundant level sensing. It includes a non-contacting ultrasonic sensor and a loop-powered pressure sensor can be connected for redundant sensing in applications with foam or grease. The unit will recalibrate the pressure sensor automatically and switch back and forth from ultrasonic level to the pressure sensor as required.

The controller is designed for sewage lift stations, wet wells and storage tanks. Calibration and relay setpoints are easy to enter through a user-friendly keypad and menu system. An automatic pump run-time logging and reporting system helps operators plan pump maintenance and identify lazy pumps before they fail. It includes an isolated 4-20 mA output and six programmable control relays for pump control, pump alternation and level alarms. Intrinsically safe sensors and a built-in data logger are optional. 888/473-9546; www.greyline.com

Odor monitoring

The OdoWatch 3.0 real-time odor monitoring system from Kruger, a Veolia Water Solutions & Technologies Company, helps wastewater treatment plants prevent odors before they become a problem. EPA-approved AERMOD modeling follows the odor plume over complex terrain.

Municipalities receive alerts when odors from a plant approach areas outside the predetermined parameters. Plants can then prioritize the processes that need the most attention so that upgrades can be planned. Plants can reduce the use of chemicals to dose odor sources and get more odor control by dosing only when needed. OdoSulf uses real-time, continuous views of the local impact of H2S. 919/677-8310; www.krugerusa.com

Packaged lift stations

MetroRail packaged lift stations from Metropolitan Industries handle raw sewage, stormwater, cooling water and other applications. Control systems can be designed to include emergency backup power systems, telemetry or SCADA panels, and local and visual alarms. Other features and control options include built-in security, safe range parameters, project specific programming, flow metering, automatic or manual transfer to emergency power sources, solid-state programming and touchscreen control.

Stations are available in fiberglass, epoxy-coated steel and stainless steel. Systems can be customized in an unlimited variety of sizes with constant or variable speed control systems available. Users can combine the company's MetroFab custom-designed, prefabricated housed systems for complete package and implementation of aboveground controls. Systems can be fully assembled and ready for easy installation. Buildings can be customized with a number of exterior finishes including exposed aggregate, simulated or real brick and more. Chemical rooms and generator rooms are also available. 815/886-9200; www.metropolitanind.com

Pump station manager

MultiSmart from MultiTrode is an intelligent pump station manager that helps reduce energy consumption and operating costs. With out-of-the-box functionality designed for fast and easy deployment, the easy-to-use unit features high-quality PLCs, RTUs and pump controllers in a comprehensive, intuitive package. Preprogrammed logic prevents failures, blockages and spills. Hundreds of custom features are easily configurable for virtually any scheme or situation.

The unit provides preventive control and maintenance. It calculates pump efficiency and decreases pump station electrical consumption by leveraging use of the most efficient pump. Remote control programming reduces maintenance and troubleshooting costs, and frequency of site visits. It includes PID controls for booster pumps, and built-in local SCADA without the added cost of HMI hardware and software. Trending pump efficiency over time ensures intelligent capital improvement programs. 561/994-8090; www.multitrode.com

Prefab structures

Shelter-Max prefab fiberglass structures from Orenco Systems are an effective, affordable solution for mechanical or electrical equipment that requires protection from the elements. They can be sized to meet almost any need.

Structures are molded in a single piece (using the vacuum infusion process), and made of 4-inch foam-cored fiberglass walls, making them strong, lightweight and watertight and protecting equipment from extremes in temperature and weather. Units are approximately 7.5 feet wide by 8.5 feet high and come in standard lengths of 7, 14, 21, 28, 35 and 42 feet. Custom lengths are also available. The units are corrosion resistant and designed to withstand temperatures from -60 degrees to 125 degrees F. They are simple to set up and are transported easily by truck, rail, cargo container, helicopter or other aircraft. 800/348-9843; www.orenco.com

Inside drops

Lift station inside drops from RELINER/Duran extend pump life by preventing aerated influent from being directly drawn into the pumps. The drops can reduce pump-related problems and provide general maintenance and odor issue reduction. The drop pipe should always be extended below the low limit level and cut to follow the slope of the base fillet. If there is no fillet, users should cut the pipe at 45 degrees and maintain a distance from the floor or fillet of one pipe diameter. This will create a diffuser by directing the flow back against the structure, which de-aerates the influents. The incoming flow should not be directed toward the pumps. This arrangement has nothing to collect rags and debris and can be cleaned from above. 800/508-6001; www.reliner.com

Standby lift station

Enviroprime standby lift station systems from Thompson Pump & Manufacturing include permanently installed standby pump units that continue pumping despite power loss or primary pump failures. The automatic self-priming pump set can meet system demands during wet weather, routine maintenance, new construction or emergency repair.

The pumps include the Enviroprime system that actively prevents sewage spills. The system uses programmable electronic controls, which make use of sensors that monitor levels in the wet well and initiate backup pumping as programmed. In addition to the SCADA-capable controls that send an alarm to alert an operator, the pumps are available with the Silent Knight canopy that reduces sound levels for residential areas. 800/767-7310; www.thompsonpump.com

Monitoring software

VTScada 10.1 monitoring and control software from Trihedral Engineering allows users to quickly and easily add engaging prebuilt lift station displays to SCADA systems. The VTS Context Tag models how lift station elements relate to each other in a hierarchical structure. For example, a lift station owns a communication driver which has two pumps that each own four I/O tags. Users draw the entire context tag at once using a lift station template. The whole process takes less than a minute. The system also features preconfigured templates for third-party devices including the MultiTrode MultiSmart RTU and the MPE Pump Controller. Graphic tolls allow users to create and reuse templates. 800/463-2783; www.trihedral.com

Data acquisition

IntelliLogger stand-alone data acquisition and alarming instruments from Logic Beach can be used for pump station monitoring and alarming, remote and customer site flow totalization and reporting, energy auditing, waste treatment plant studies and more. The network-enabled units can be connected to the Internet via LAN or cellular modem. With Internet connectivity, the units can send out status or alarm emails and text messages, FTP logged data back to central servers and serve standard and user-designed custom Web pages to a browser.

The units accept analog, digital and Modbus inputs and offer I/O expansion via bus connection expansion modules. Isolated inputs, 18-bit resolution and field-configurable input types provide quick interface to most signal and sensor types. With the company's HyperWare-II software, users can quickly program the units to process input signals mathematically, totalize, perform flow calculations, recognize and output alarms, send reports and store to local memory within the unit. HyperWare-II uses icon-based, drag-and-drop programming so it is quick to learn, intuitive and included with the IntelliLogger. Models range from the low-cost, battery-powered IntelliLogger-Mini to the full Network Enabled IntelliLogger IL-80. Packaged systems are stocked and weatherproof and offer industrial frames. 619/698-3300; www.logicbeach.com