Proving the effectiveness in resisting infiltration and corrosion

Municipal governments and other infrastructure owners are increasingly taking an interest in understanding rehabilitation methods to prevent groundwater infiltration and corrosion in wastewater structures. SpectraShield has participated in three independent studies for the evaluation of effectiveness in resisting infiltration and corrosion.

In 1996 SpectraShield participated in the CIGMAT program at the University of Houston. The objective of the study was to evaluate SpectraShield for adhesion, resistance to external hydrostatic pressure, and chemical resistance. SpectraShield passed in all three categories.

In 2013 SpectraShield was evaluated by the U.S. Army Corps of Engineers at Fort Bragg, North Carolina. The Corps released their report and findings in April 2016 and rated SpectraShield with a return on investment of 5.5.

In 2017 SpectraShield was evaluated by The Geo Engineering Centre at Queen’s University, Kingston, Ontario, for resistance to external water pressure. The test was conducted to over 120 feet of hydrostatic pressure and the SpectraShield Liner remained intact.

800-284-2030; www.spectrashield.com.

City makes flood-mitigation improvements

Problem:

In the summer of 2016, the city of Miami Beach, Florida, in partnership with the Florida Department of Transportation, implemented a flood- mitigation program along the Indian Creek Drive/SR A1A corridor. The improvement included the installation of a pump station and elevation of the existing roadway and sidewalks to implement enhanced flooding solutions to the area. The pumping station required a 72-inch pipe to convey stormwater runoff from the pump station in Miami Beach to a nearby outfall. The project site was in a very tight construction space, located adjacent to a roadway on one side and a canal along the other side.

Solution:

The consulting engineer, Ribbeck Engineering, and the general contractor, David Mancini & Sons, worked together to identify the most effective and cost-efficient solution. They selected 3,400 linear feet of 72-inch DuroMaxx SRPE pipe manufactured by Contech Engineered Solutions to convey the water from the pump station to the outfall. The pipe offers a watertight joint, laying lengths of 24 feet, a smooth interior for improved hydraulics, and durability. The drainage system included inline elbows, access risers and lateral connections for 24-inch-diameter A-2000 PVC for an effective drainage solution.

Result:

Both the city and Florida Department of Transportation were satisfied with the result as the surrounding community will greatly benefit from these flood-mitigation improvements to Indian Creek Drive.

800-338-1122; www.conteches.com.

Lining system provides solution for tricky infrastructure crack repairs

Problem:

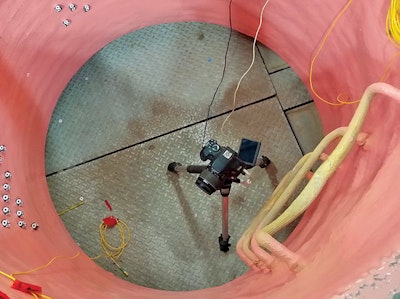

An inspection determined that a Texas digester had severe deterioration, including deep cracks along the floor that were leaking water in areas throughout the unit. The number of cracks and leaks suggested that the water membrane underneath the slab may have aged and fatigued.

Solution:

The severity of the cracks and nature of the deterioration led to a creative solution combining Epoxytec’s CPP Sprayliner and CPP trowelable. After surface prep, the concrete was sprayed with an initial coat of CPP Sprayliner to achieve an even finish and to seal any hairline cracks and low-pressure leaks. After allowing the initial coat to cure, drilling on some major leaking areas was conducted to alleviate pressure away from the cracks. Next, standard CPP was applied to these open cracks to finalize the repairs (now with no pressure). Once the majority of the cracks were sealed and repaired and the material was cured, the contractor grouted the relief drill holes and patched them with CPP trowelable. The final step included spraying a coat of CPP Sprayliner to make all the surfaces uniform.

Result:

All cracks were addressed, and CPP Sprayliner provided sealed protection that will prevent corrosion and future deterioration. This solution resulted in enormous cost-savings for the end user and allowed a quick return to service without replacement or major reconstruction.

877-463-7699; www.epoxytec.com.

Radar gets accurate level measurement in challenging lift station

Problem:

A wastewater treatment plant in New York’s Hudson Valley had been trying for years to get an accurate level reading in their lift stations. Unfortunately, every technology they tried — floats, gauges, pressure sensors and ultrasonic devices — eventually failed. Problems were caused by steam, high humidity, grease, rags and even an instance of spiders getting in the way. They needed a noncontact technology that would work in this environment.

Solution:

VEGA Americas suggested the VEGAPULS WL 61, a radar sensor designed to make accurate measurements independent of the product, process and ambient conditions.

Result:

The plant hasn’t had a single error in its level measurement since the unit was installed. Technicians were even able to adjust the radar sensor to ignore certain structural components inside the lift station. The customer was so pleased with the results, they bought a second unit as a backup, removed all other level sensors from that lift station, and purchased many more for other difficult situations. 800-367-5383; www.vega.com.